Working papers are intended to make results of my ongoing research available to others and to encourage further discussion on the topic. Comments and clarification are welcome.

A number of developments have occurred since publication of my article, M8A1 Scabbards Produced at the Pennsylvania Working Home for the Blind (ref. SABC Journal Volume 91, Spring 2015). Recently-discovered evidence identified an error in my previous analysis concerning Viz Manufacturing Co’s. production of M8A1 scabbards that is corrected herein.

This paper provides a brief history of Viz Manufacturing Co. and outlines their scabbard production. It also shows how Viz Manufacturing Co’s influence on M8A1 scabbard production likely went beyond just the scabbards marked VIZ. The paper explains how past work by multiple collectors/researchers, along with a recent development, finally led to identification of the M8A1 scabbard manufacturer represented by “WD.” The paper provides a brief history of that firm and describes what can be deduced regarding their production of M8A1 scabbards.

The paper concludes with implications these new findings have for M8A1 scabbard production at the Pennsylvania Working Home and a listing of still-unanswered questions for further research.

Viz Manufacturing Co.

The firm we know as Viz Manufacturing Co. was created by Victor I. Zelov. Born, Victor Tzelovalnikoff, in Russia, he studied engineering in St. Petersburg and served as a naval engineer in Tsarist Russia. As the Russian Revolution threatened communist rule, he obtained permission to study abroad. In 1917, he went to Sweden. In 1918, he emigrated to the U.S. at age 24. He changed his name to Victor Ivan Zelov and became a U.S. citizen.[1]

He started working as a mechanic in the Camden, NJ, shipyards until he met another Russian naval engineer. In 1920, they started their own company, Vibration Specialty Co. The company produced devices and instruments to reduce vibration in large rotary parts (e.g., steam turbines, ship’s propellors).

During the 1920s, Zelov collaborated with another Russian immigrant who was an engineering professor at the University of Pennsylvania, developing an automatic steering device for ships. The market for this device was limited, so Zelov approached Harold Pitcairn, of the Pitcairn Aircraft Co., to adapt the device for aircraft use. They each put up $15,000 to form Aircraft Control Corp. Aircraft Control Corp. developed highly-advanced airspeed and altimeter instruments, which resulted in Zelov’s first defense contracts. In 1930, the company was bought by the Bendix Corporation.

Zelov received $50,000, plus a lucrative 10-year employment deal with Bendix. He found that the job was a sinecure (pay and title, but nothing meaningful to do) and became bored. In 1932, he traded the employment deal for 100 percent ownership of Bendix’ Molded Insulation Co. located in the Germantown District of Philadelphia, PA. This marked the beginning of what we know as Viz Manufacturing Co. The company name remained Molded Insulation Co., Inc. until 1965, when Zelov formally changed it to Viz Manufacturing Co., Inc. However, I will refer to the company as Viz Manufacturing Co. unless necessary to do otherwise, since this is the name most familiar to readers.

Zelov began making molded plastic parts for the Navy and automotive industry, then began making electrical assemblies, and finally moved into electronics manufacturing. By 1950, he began making commercial electronics under the VIZ-brand.

Zelov’s lasting claim to fame is his development of an improved radiosonde device used to collect weather data. Radiosondes are carried aloft on weather balloons, transmitting weather data to a ground receiver. His version cost less than half what his competitors offered and provided more capability. During the 1950s, 60s, and 70s, Viz Manufacturing Co. accounted for half of worldwide production, selling millions of radiosonde units to the U.S. Military, the National Weather Service, and in dozens of foreign countries.

In the 1970s, Zelov acquired ownership of the RCA Instruments Division and began making VIZ-branded electronic test instruments.

Zelov operated the company solely on a cash basis. He always kept the company just below 500 employees (498 to be precise). This ensured his being given small-employer preferences in federal government contracting. [2] This self-imposed workforce limitation appears to have had an unexpected and profound impact on M8A1 scabbard production.

Zelov’s son, Victor H. Zelov, served as a B-24 navigator during the Second World War, then earned an engineering degree and joined the company.[3] His younger son, Randolph, graduated from the Naval Academy in 1948 and served on submarines. He, too, joined the company after completing a 20-year career as a Naval Officer.[4] The senior Zelov worked full-time past his 90th birthday[5], passing away in 1985 at the age of 91.[6] In 1997, the company was acquired by the naval engineering firm, Sippican Inc., who moved production work to Mexico and closed the Philadelphia plant.[7]

Viz Manufacturing Co. Scabbard Production

Viz Manufacturing Co. produced four different scabbard types:

Scabbard, Bayonet-Knife, M8A1;

Sheath, Machete (2 Types); and,

Scabbard, Bayonet M1917.

M8A1 Scabbards—

My prior research found only one Federal Supply Class 1095—Miscellaneous Weapons contract with Viz Manufacturing Co. My analysis was that this contract, dated May 1969, was likely for production of M8A1 Scabbards.[8] A recent development has conclusively shown this to have been in error.

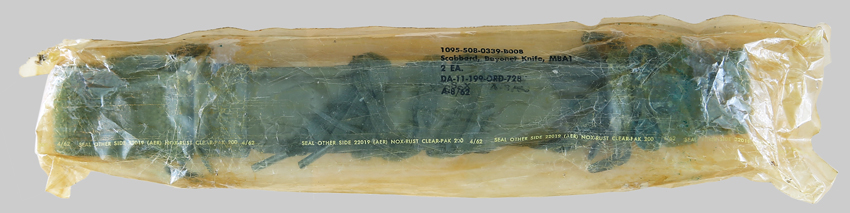

In August 2020, surplus dealer, Dupage Trading Co., offered for sale pairs of unissued M8A1 Scabbards sealed in the original cellophane wrapping. These were advertised as having 1967-68 dates. The expectation was that these were scabbards assembled at the Pennsylvania Working Home for the Blind (Pennsylvania Working Home). Collector/researcher Boyd M. Jenkinson Jr. ordered some of these packages to find that several had a printed August 1962 date and stamped March 1963 packing date. These 1963-dated packages all contained new Viz Manufacturing Co. scabbards.[9] Figures 2 through 4 show the packaged scabbards, label detail, and manufacturer symbol used by Viz Manufacturing Co. on M8A1 scabbards.

Figures 2–4: Pair of Viz Manufacturing Co. M8A1 scabbards sealed in the 1963-dated cellophane factory wrapper. The cellophane has yellowed from exposure to UV light, indicating that its cardboard carton has been absent for many years. (Author’s Collection)

Figures 2–4: Pair of Viz Manufacturing Co. M8A1 scabbards sealed in the 1963-dated cellophane factory wrapper. The cellophane has yellowed from exposure to UV light, indicating that its cardboard carton has been absent for many years. (Author’s Collection)

Boyd immediately recognized the significance of his discovery and brought it forward for discussion on the U.S. Militaria Forum. This discovery conclusively places Viz Manufacturing Co. production of M8A1 scabbards earlier than had been previously understood. The available federal contract data only goes back to 1965, so the existence of such an early contract went undiscovered.

This discovery reopens the question of how many M8A1 scabbards Viz Manufacturing Co. produced. The previously published number of 50,000 is erroneous (my fault) and is likely too low. Without knowing the dollar amount of the 1962 contract, there is no way to estimate how many scabbards that Viz Manufacturing Co. may have produced.

Plastic Machete Sheaths—

There were two machete sheath types produced by Viz Manufacturing Co. There were also two Defense Supply Agency, Textiles, Clothing & Equipage Program contracts with Viz Manufacturing Co. for Federal Supply Class 8465—Individual Equipment:[10]

- Federal Stock Number 8465-257-4321—was based on the plastic machete sheath introduced by Beckwith Manufacturing Co. late in the Second World War. As shown in Figure 5, this type had a solid plastic body with a blackened metal throatpiece. As shown in Figure 6, examples made by Viz Manufacturing Co. had the wire belt hanger placed at an angle to make the machete easier to withdraw and sheathe.

My previous research found a June 1966, $406,000, contract with Viz Manufacturing Co. Completion of this contract was expected by April 1967. [11] Figure 6 shows the marking used by Viz Manufacturing Co. on the first type machete sheath produced 1966–67.

Figures 5 & 6: First type of machete sheath produced by Viz Manufacturing Co. Manufacturer's marking and production year 1966. (Frank Trzaska)

Figures 5 & 6: First type of machete sheath produced by Viz Manufacturing Co. Manufacturer's marking and production year 1966. (Frank Trzaska)

- Federal Stock Number 8465-926-4932—was a new type adopted ca. 1966. As shown in figure 7, this design had a perforated plastic body and an integral steel sharpening device. A November 1966, $47,000, contract missed in my previous research was likely for this new type. Completion of this contract was expected by July 1967.[12] Figure 8 shows the manufacturer symbol used by Viz Manufacturing Co. on the new type machete sheath produced in 1967.

Figures 7 & 8: New type of machete sheath produced by Viz Manufacturing Co. Manufacturer's marking and production year 1967.

Figures 7 & 8: New type of machete sheath produced by Viz Manufacturing Co. Manufacturer's marking and production year 1967.

Plastic M1917 Scabbards—

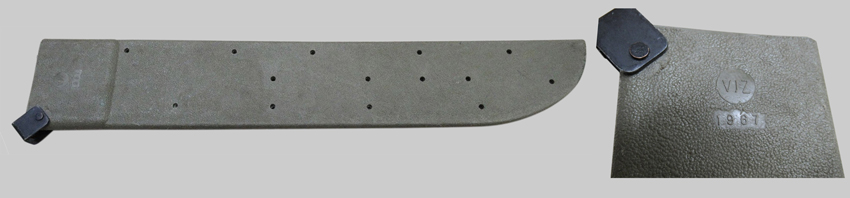

As Dan Morrison correctly indicates in his 2017 book, The U.S. Enfield Bayonet, the Viz Manufacturing Co. 1969 Weapons Program contract was actually for plastic M1917 scabbards. [13] Figures 9 and 10 show the printed label from a plastic M1917 scabbard package with Viz Manufacturing Co’s. 1969 contract number and the manufacturer symbol used by Viz Manufacturing Co. on plastic M1917 scabbards.

Figures 9 & 10: Printed label on packaging of Viz Manufacturing Co. plastic M1917 scabbard showing the 1969 contract number and April 1970 packing date. (Frank Trzaska) Manufacturer symbol on Viz Manufacturing Co. plastic M1917 scabbard. Author’s Collection)

Figures 9 & 10: Printed label on packaging of Viz Manufacturing Co. plastic M1917 scabbard showing the 1969 contract number and April 1970 packing date. (Frank Trzaska) Manufacturer symbol on Viz Manufacturing Co. plastic M1917 scabbard. Author’s Collection)

The Military Assistance Program (MAP) unit cost attributed to the plastic M1917 scabbard in 1966 was $7.18.[14] Adjusted for inflation, the estimated unit cost for Viz Manufacturing’s 1969 contract would be approximately $7.69.[15] The 1969 contract was for $69,000[16], which would yield a rough estimate of approximately 9,000 plastic M1917 scabbards produced by Viz Manufacturing Co.

Markings Used on Scabbards Produced by Viz Manufacturing Co.—

Something requiring explanation is how the scabbards produced by Viz Manufacturing Co. came to be marked differently. The two- or three-letter codes found on many 1960s scabbards are known in the Department of Defense (DOD) as “Manufacturer Symbols.” These are unique identifiers officially assigned to certain contractors by DOD.[17]

As shown in Table 1, bureaucratic inconsistencies similar to those previously found with the Pennsylvania Working Home’s contracts[18] resulted in creation of a new contractor identity for “Viz Mfg. Co.” well before the 1965 corporate name change; and the continued letting of new contracts under the company’s original “Molded Insulation Co. Inc.” identity as late as June 1967.

| Table 1: Contractor Numbers and Names Used Concurrently | ||

| Contractor Number | Contractor Name | Contract Beginning Dates |

| 618060 | Molded Insulation Co Inc | Thru June 1967 |

| 921317 | Viz Mfg Co | ? (at least since August 1962) |

| NARA/AAD, Records of Prime Contracts Awarded by the Military Services and Agencies 7/1/1965–6/30/1975 | ||

The concurrent use of two contractor identities for the same company likely enabled VIZ to be used on M8A1 scabbards in 1962–63 despite it not being officially assigned, instead of the company’s officially-assigned symbol “ML.”[19] When the company formally changed its name to Viz Manufacturing Co., DOD found that another firm, Curtis Mfg. Co. - Visioneering-Bunnel Division, of Cleveland, OH, was already assigned the symbol VIZ.[20]

Both plastic machete sheath contracts were signed in 1966 as this issue was being sorted out. The first type machete sheath made in 1966–67 was not marked VIZ. Instead, the marking was, verbatim, the contractor’s name as it appeared on the contract’s Individual Procurement Action Report, DOD Form 350, “Viz Mfg Co.”[21] This seems a sensible expedient in light of DOD having discovered that VIZ was assigned to another contractor. Once again, bureaucratic inconsistency reared its head. The new type plastic machete sheath made later in 1967 was, inexplicably, marked VIZ.

Eventually, VZM was assigned as the company’s “new symbol.” DOD designated ML as the firm’s “old symbol,” that could no longer be used by Viz Manufacturing Co. nor assigned to another contractor.[22] This is how VZM came to be used on M1917 scabbards.

Identifying the M8A1 Scabbard Manufacturer Represented by WD

Identification of the manufacturer represented by WD eluded researchers for many years. Three, seemingly, contradictory observations vexed the collecting community:

- On one hand, as shown in figure 11, the “VIZ/WD” throatpiece marking appears to be such that the “WD” was added to an existing VIZ-marked throatpiece.

Figure 11: M8A1 scabbard throatpiece showing the apparent addition of WD to an existing VIZ manufacturer symbol. (Author’s Collection)

This suggested that WD scabbard production commenced after Viz Manufacturing Co. M8A1 production, initially utilizing parts supplied by Viz Manufacturing Co. Then, as shown in Figure 12, WD subsequently produced additional scabbards where the throatpieces were marked only WD.

Figure 12: M8A1 scabbard throatpiece with only the WD manufacturer symbol. (Author’s Collection)

- On the other hand, as shown in Figure 13, Gary Cunningham’s and Marvin Binder’s research observed that some of the WD-marked scabbards had throatpieces and scabbard bodies with Victory Plastics Co. markings (the ‘Vp” mark on the underside of the steel top plate and “Vp” mold marks on the reverse of the plastic body).[23] The final Victory Plastics Co. M8A1 scabbard contract was completed in 1961.[24] This suggested that WD scabbard production may have commenced before Viz Manufacturing Co.

Figure 13: Victory Plastics Co. manufacturing markings observed on a WD-marked M8A1 scabbard. These markings have not been observed on scabbards marked VIZ/WD. (Author’s Collection)

Figure 13: Victory Plastics Co. manufacturing markings observed on a WD-marked M8A1 scabbard. These markings have not been observed on scabbards marked VIZ/WD. (Author’s Collection)

- Thirdly, VIZ/WD-marked scabbards did not exhibit Victory Plastics Co. production marks. This suggested that, perhaps, WD-marked scabbards were made before VIZ/WD-marked scabbards.[25]

Establishing Viz Manufacturing Co’s. M8A1 production in 1962–63 helped reconcile WD’s use of parts manufactured by both Victory Plastics Co. and Viz Manufacturing Co., moving the likely timeframe for WD scabbard production back to ca. 1962–65.

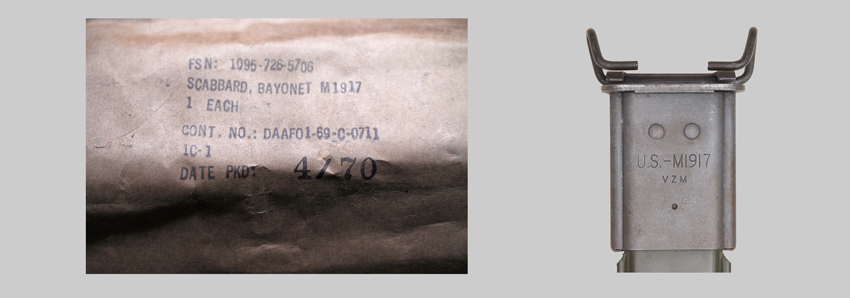

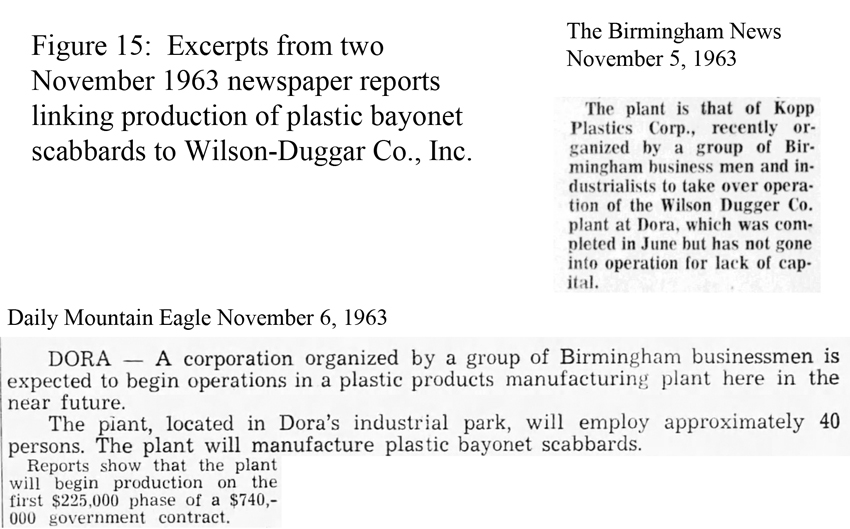

This helps explain why it has been so difficult to identify the firm represented by WD, as their production may have occurred during the post-Victory Plastics/pre-1965 period for which no federal contract data is readily available. Since there was no contract data available, I turned to searching old newspapers ca. 1962–65. I found reporting in 1963 about a federal government contract for manufacturing plastic bayonet scabbards at the factory of a rural Alabama company:

Wilson-Duggar Co., Inc. of Jasper, Alabama.[26]

Wilson-Duggar Co., Inc.

The story of Wilson-Duggar Co. is in many ways the opposite of Viz Manufacturing Co. Wilson-Duggar Co. was a pipe dream to build a toy factory by three politically-connected Jasper, Alabama, locals that didn’t get beyond the start-up money provided by the federal government.

Brothers Robert T. and Harold A. Wilson were sons of a coal-miner. They became lawyers and, in 1950, opened a practice in Jasper. Robert was elected to the Alabama State Senate in 1962, serving until 1966; and again 1970–78. At the 1972 Democratic National Convention, he nominated Gov. George Wallace for President.[27] Another Jasper native, Robert G. “Jerry” Duggar, developed a design for Magnetic Toy Building Blocks, which he first patented in 1957.[28]

Walker County, Alabama, was an impoverished rural area whose major industry had been coal-mining. Closing of the last big mines in the early 1950s left the area economically-disadvantaged.[29] The Area Development Act of 1961 was signed into law by President Kennedy in May 1961, the first federal program to provide business development funding to rural areas suffering from chronic unemployment or underemployment.[30]

With $2,200 in capital, the three men incorporated Wilson-Duggar Co., Inc. on November 29, 1961.[31] They were successful in building local popular support; and, with assistance from Senator Lister Hill and Representative Carl Elliott, obtained $586,000 in Area Development Act funding to build a toy factory in the nearby town of Dora (the men contributed $8,925).[32] This required approval of the Dora Industrial Development Board and Dora Gas Board, both of which Robert T. Willson had served as general counsel.[33]

The Dora Gas Board and Dora Industrial Development Board were on the hook for the majority of the federal funding: $410,000 was loaned to the Gas Board to put in a gas distribution system and $157,950 was loaned to the Industrial Development Board to build the factory and install a water main. The Industrial Development Board would own the factory and its machinery, which it would lease to Wilson-Duggar Co.[34]

This was big news in Walker County, as the toy factory was expected to eventually employ 120. Over 500 people stood in 90-degree heat to attend the groundbreaking ceremony on August 18, 1962. Robert T. Wilson, then a nominee for Alabama State Senate, served as master of ceremonies. Rep. Elliott was keynote speaker. [35]

Figure 14: Press photo from the Wilson-Duggar Co. factory groundbreaking ceremony. (copyrighted image reproduced with permission from Daily Mountain Eagle, Jasper, AL)

Construction of the Wilson-Duggar Co. factory was followed enthusiastically by the local newspaper, which reported regularly on the progress being made. In November 1962, the factory was reported to be 25 percent complete.[36] In December, it was reported 80 percent complete. In January 1963, the building was to be turned over to the company.[37] In April, the company reported that they were awaiting arrival of necessary equipment.[38] By the time the factory was completed in June 1963, those who bought into the pipe dream had a rude awakening. Wilson-Duggar Co. had run out of money and were unable to begin manufacturing operations.[39]

This likely created a predicament where neither the Dora Boards nor Sen. Hill and Rep. Elliott could afford to let the Wilson-Duggar Co. factory fail without bringing in any revenue to repay the federal loans. In November 1963, a group of Birmingham businessmen, headed up by former Ingalls Iron Works Co. President, John B. Kopp, were brought in as fixers to take over Wilson-Duggar Co. factory operations. The factory was reportedly to begin production on the first $225,000 phase of a $740,000 federal government contract to produce plastic bayonet scabbards. The factory was reported to employ 40 persons.[40]

I found no subsequent information regarding either Wilson-Duggar Co., Inc. or Kopp Plastics Corp. that went beyond the production of bayonet scabbards:

- A search of Dora, AL, white pages directories only found listings for Wilson-Duggar Co. Inc. from 1963–66, indicating they were in the business of “molded prods.”[41]

- A similar search of Birmingham, AL, white pages directories found no listings whatever for Kopp Plastics Corp.[42] Neither the State of Alabama nor the 1965–75 federal prime contractor database have record of a business entity by that name. It appears that the Kopp Plastics Corp. name was only used for the effort to rescue the Dora redevelopment project.

M8A1 Scabbard Production by Wilson-Duggar Co., Inc.

Rock Island Arsenal issued Army solicitation AMG/W/-11-119-63-562 on April 12, 1963, for a minimum quantity of 144,415 and maximum quantity of 600,000 M8A1 scabbards. This solicitation was set-aside exclusively for small businesses, so the rules for determining eligibility for small business contracting preferences were different from the usual <500 employees. Solicitations were sent to 41 potential bidders, resulting in 4 bids which were opened May 13, 1963. Table 2 lists the four bidders and their bids.

| Table 2: Bids Received in Response to Solicitation AMG/W/-11-119-63-562 | |

| Bidder | Minimum Quantity Bid Amount |

| Molded Insulation Co. (aka Viz Mfg. Co.) | $207,063.96 |

| Wilson-Duggar Co., Inc. | $208,351.51 |

| Lasko Metal Products Co. | $230,386.56 |

| Victory Plastics Co. | $236,729.17 |

| Government Accounting Office, Procurement Law Division, Bid Protest Decision B-152179, September 24, 1963 | |

Although Viz Manufacturing Co’s. bid was marginally-lower than Wilson-Duggar Co’s., Wilson-Duggar Co. received small business preferences while Viz Manufacturing Co. did not. This resulted in Wilson-Duggar Co. being awarded the contract on July 12, 1963. Viz Manufacturing Co. subsequently protested not being considered a small business for purposes of this solicitation. On September 24, 1963, the Government Accounting Office, Procurement Law Division, held that the contract award was proper and dismissed the protest.[43]

The Wilson-Duggar Co. M8A1 scabbards would have been produced during 1964, perhaps, into 1965. While evidence clearly identifies Wilson-Duggar Co. as the manufacturer, there is no hard evidence regarding the extent of their manufacturing process. Observations and circumstantial evidence can tell us some about what likely did and did not occur:

- Evidence is clear that Wilson-Duggar Co. assembled scabbards using subassemblies (steel throatpieces and plastic bodies) procured from both Victory Plastics Co. and Viz Manufacturing Co.

- It is unclear whether Wilson-Duggar Co. eventually manufactured their own subassemblies or whether they were all externally-supplied (presumably, by Viz Manufacturing Co.). Wilson-Duggar Co’s. disappearance after scabbard production began at the Pennsylvania Working Home suggests that they may not have ever manufactured subassemblies.

The Pennsylvania Working Home consumed all of the plastic scabbard bodies that could be externally-supplied (and would have taken even more if they were to be had).[44] If Wilson-Duggar Co. manufactured subassemblies, both factories could have produced scabbards concurrently. (And, the DOD wanted more M8A1 scabbards than they were able to get from the Pennsylvania Working Home.[45])

- There are reasons why it may have been in the players’ interests to supply Wilson-Duggar Co.:

- Having failed to realize M8A1 scabbard contracts in both 1962 and 1963, the The Victory Plastics Co. factory closed in 1964, so they stood to benefit by disposing of subassemblies left over from their 1960 contract.

- In 1964, Demand for VIZ radiosondes was booming. Viz also had other DOD contracts for sensitive military electronics and a history of substantial backlogs of defense orders.[46]

Viz supplying subassemblies would have helped the DOD mitigate risks to scheduled scabbard deliveries inherent in switching production to a new factory. Supplying subassemblies would enable Viz to receive a portion of the revenues from the “lost” contract and simply redirect the scabbard assembly portion of its workforce to other government contracts.

- Having failed to realize M8A1 scabbard contracts in both 1962 and 1963, the The Victory Plastics Co. factory closed in 1964, so they stood to benefit by disposing of subassemblies left over from their 1960 contract.

- The use of externally-supplied subassemblies suggests that Wilson-Duggar Co. may have encountered difficulties initiating production on time. Victory Plastics Co. and Viz Manufacturing Co. both supplying subassemblies suggests that the DOD probably had a hand in coordinating this.

Evidence is lacking regarding how much of the contract that Wilson-Duggar Co. actually completed. This makes it impossible to estimate how many scabbards that Wilson-Duggar Co. may have produced.

Subsequent events suggest that things may not have gone well. 1965 saw U.S. ground forces take the offensive in Vietnam, increasing troop levels from 23,000 to 184,000. This would seem the worst possible time for the DOD to, again, relocate scabbard assembly to a new factory. However, the DOD did just that, making the Pennsylvania Working Home prime contractor effective July 1965. [47] By 1966, Wilson-Duggar Co. was apparently defunct.

Implications for Production of M8A1 Scabbards at the Pennsylvania Working Home

While Wilson-Duggar Co’s. production may not have been a business success, it may have modeled a new way of producing M8A1 scabbards, foreshadowing the assembly of some 4 million scabbards at the Pennsylvania Working Home.

Establishing Viz Manufacturing Co’s. production in 1962–63 and Wilson-Duggar Co’s. production in 1964–65, leaves the Pennsylvania Working Home as the apparent final producer of U.S. Government M8A1 scabbards 1965–1970.[48] The M10 scabbard design is believed to have been adopted ca. 1970. No evidence of further U.S. Government M4–M7 bayonet-knife scabbard production has been found until the first M10 scabbard contracts were let ca. 1985.[49]

Hard evidence is still lacking regarding the supplier of subassemblies to the Pennsylvania Working Home. However, circumstantial evidence that came to light while writing this paper consistently points to Viz Manufacturing Co. as the likely supplier:

- Viz Manufacturing Co. produced M8A1 scabbards before assembly began at the Pennsylvania Working Home. Viz Manufacturing Co. supplied some (if not most) of the subassemblies used by Wilson-Duggar Co., the Working Home’s immediate predecessor.

- Experience with Wilson-Duggar Co. likely underscored for federal contract managers, the benefits of having a competent supplier nearby the assembly plant to help with production problems. The Pennsylvania Working Home was located less than 9 miles from Viz Manufacturing Co.

- Victor Zelov was personally involved with the Pennsylvania Working Home. In 1965, and through at least 1967, Zelov was on the Working Home’s Board of Managers.[50]

- My previous article on the Pennsylvania Working Home described how, in 1967, federal contract managers wanted increased scabbard production and chafed because they could not realize the desired quantity (150,000/mo.) due to an insufficient supply of plastic scabbard bodies.[51] In July 1969, reporting on National Industries for the Blind cited monthly scabbard production having reached 125,000/mo.[52]

Limited capacity to produce scabbard bodies is consistent with Viz Manufacturing Co’s. unwillingness to increase its limited workforce, something in 55 years of running the company, Victor Zelov never did.[53]

Unanswered Questions

Questions still remain, requiring further evidence to confirm:

- How many M8A1 scabbards were produced by Viz Manufacturing Co.?

- How many M8A1 scabbards were produced by Wilson-Duggar Co.?

- Did Wilson-Duggar Co. ever manufacture steel and/or plastic subassemblies?

- Who supplied subassemblies used in M8A1 scabbard production at the Pennsylvania Working Home?

Conclusion

While there still remains a need for additional research, the discovery that Viz Manufacturing Co. produced M8A1 scabbards earlier than was previously thought has led to significant advances in our understanding of M8A1 scabbard production. A deeper understanding of Victor Zelov and Viz Manufacturing Co. shows that their influence on M8A1 scabbard production was likely greater than was previously understood. Wilson-Duggar Co’s. involvement in M8A1 scabbard production, although peculiar, may have been a game-changer that set the stage for the balance of M8A1 scabbard production.

This paper also demonstrates how collaboration between collectors/researchers over many years can pay dividends that add to the body of knowledge beyond what any individual effort or discovery might achieve. The work of Marvin Binder, Gary Cunningham, and Boyd Jenkinson Jr. greatly helped enable identification of the firm represented by WD and make sense out of their production of M8A1 scabbards. I also want to thank Frank Trzaska for his generous support in locating some critically-important images needed to illustrate Viz Manufacturing Co. scabbard production.

[1] Ancestry.com. California, Pennsylvania, U.S., Federal Naturalization Records, 1795-1931 [database on-line], Petition for Naturalization 63941, accessed May 22, 2021, Ancestry.com.

[2] Dominic Sama, “A Business Succeeds Without Following Some Textbook Rules”, The Philadelphia Inquirer (Philadelphia, PA), Sun, Apr 3, 1977, Pages 32 & 37 Newspapers.com

[3] Obituary, “Victor Hopkins Zelov”, The Philadelphia Inquirer (Philadelphia, PA), Thu, Apr 29, 1999, Page B5 Newspapers.com

[4] Obituary, “Randolph Dickinson Zelov”, The Philadelphia Inquirer (Philadelphia, PA), Sat, Feb 23, 2008, Page B4 Newspapers.com

[5] People in the News, “After a Half-Century as Boss, Time Off for His Birthday” The Philadelphia Inquirer (Philadelphia, PA), Mon, Jul 9, 1984, Page 2-C Newspapers.com

[6] Deaths, “Manufacturer Victor Zelov”, The Philadelphia Daily News (Philadelphia, PA), Tue, Jul 23, 1985, Page 34 Newspapers.com

[7] John Estrella, Sippican Buys Philadelphia Firm, SouthCoast Today (a USA Today online publication), last updated Jan 11, 2011, accessed May 18, 2021, https://www.southcoasttoday.com/article/19971205/news/312059968

[8] Ralph E. Cobb, M8A1 Scabbards Produced at the Pennsylvania Working Home for the Blind, Journal of the Society of American Bayonet Collectors, Volume 91 (Spring 2015), pages 7-8.

[9] Boyd M. Jenkinson, Jr. (slufstuff), NOS US VIZ M8A1 scabbards dated 1963 , U.S. Militaria Forum, August 20, 2020, https://www.usmilitariaforum.com/forums/index.php?/topic/346417-nos-us-viz-m8a1-scabbards-dated-1963/

[10] NARA/AAD, Records of Prime Contracts Awarded by the Military Services and Agencies, created, 7/1/1965–6/30/1975, documenting the period 7/1/1965–6/30/1975, accessed June 6, 2021, http://aad.archives.gov/aad/series-description.jsp?s=492&cat=SB297&bc=sb,sl

[11] NARA/AAD, Records of Prime Contracts ...

[12] NARA/AAD, Records of Prime Contracts ...

[13] Daniel Jay Morrison, The U.S. Enfield Bayonet, (Demarest, NJ 2017), page 289 and endnote 34.

[14] National Archives and Records Administration, Access to Archival Databases (AAD), Records About Military Goods and Services Provided to Foreign Countries, created, ca. 10/1/1950 - 9/30/2004, documenting the period ca. 10/1/1950 - 9/30/2004, accessed May 18, 2021, https://aad.archives.gov/aad/series-description.jsp?s=3284&cat=GS30&bc=,sl

[15] Consumer Price Index, 1913- Federal Reserve Bank of Minneapolis, accessed May 27, 2021, https://www.minneapolisfed.org/about-us/monetary-policy/inflation-calculator/consumer-price-index-1913-

[16] NARA/AAD, Records of Prime Contracts ...

[17] Department of Defense Handbook, Ammunition Manufacturers and Their Symbols, (Washington DC, Department of Defense, 1998), pages 1–6.

[18] Cobb, M8A1 Scabbards Produced at the Pennsylvania Working Home for the Blind, 5–6.

[19] Ammunition Manufacturers and Their Symbols, pages A-224 and B-51.

[20] ibid, pages A-90 and B-82.

[21] NARA/AAD, Records of Prime Contracts ...

[22] Ammunition Manufacturers and Their Symbols, pages A-224, A-348, and B-83.

[23] Gary Cunningham (bayonetman), The Elusive WD M8A1 Scabbard, U.S. Militaria Forum, December 31, 2015, https://www.usmilitariaforum.com/forums/index.php?/topic/257458-the-elusive-wd-m8a1-scabbard/

Marvin Binder (Misfit 45), VIZ/WD scabbard with VIZ and WD scabbards, U.S. Militaria Forum, January 7, 2021, https://www.usmilitariaforum.com/forums/index.php?/topic/352125-vizwd-scabbard-with-viz-and-wd-scabbards/

[24] Gary Cunningham, “Bayonet Points 7,” U.S. Military Knives (April 2003), accessed May 18, 2021, http://www.usmilitaryknives.com/bayo_points_7.htm

[25] Cunningham, The Elusive WD M8A1 Scabbard and Binder VIZ/WD scabbard with VIZ and WD scabbards.

[26] “Kopp Plastics to Begin Work”, Daily Mountain Eagle (Jasper, AL), Wed, Nov 6, 1963, Page 1 Newspapers.com

[27] Associated Press, “Ex-State legislator Robert Wilson Sr. Dies”, Montgomery Advertiser (Montgomery, AL), Wed, Mon Jul 28, 1997, Page 4B Newspapers.com

[28] Robert G. Duggar, Magnetic Toy Building Blocks, Patents 2939243, filed Aug 8, 1957, and issued June 7, 1960, https://patents.google.com/patent/US2939243 and 3254440, filed May 21, 1962, and issued June 7, 1966, https://patents.google.com/patent/US3254440.

[29] “Construction Excites Area”, Daily Mountain Eagle (Jasper, AL), Fri, Nov 16, 1962, Page 1 Newspapers.com

[30] Wikipedia, s.v. Area Redevelopment Administration, last modified April 7, 2021, https://en.wikipedia.org/wiki/Area_Redevelopment_Administration

[31] Alabama Secretary of State, Business Entity Records, Entity ID Number 811-779, accessed May 19, 2021, https://arc-sos.state.al.us/cgi/corpdetail.mbr/detail?corp=811779

[32] “Area Development Administration Okays Loans Totaling Almost $586,000 for Dora”, Financial Assistance to Help Toy Company, Daily Mountain Eagle (Jasper, AL), Fri, Aug 10, 1962, Page 1 Newspapers.com

[33] “Rep. Elliott Praises County’s Spirit in Wilson-Duggar Groundbreaking”, Daily Mountain Eagle (Jasper, AL), Fri, Aug 20, 1962, Page 1 Newspapers.com

[34] “Area Development Administration Okays Loans Totaling Almost $586,000 for Dora”

[35] “Rep. Elliott Praises County’s Spirit in Wilson-Duggar Groundbreaking”

[36] “Construction Excites Area”

[37] “World Wide Fabricating Co. Begins Work on Building”, Daily Mountain Eagle (Jasper, AL), Fri, Jan 4, 1963, Page 1 Newspapers.com

[38] Tim Robinson, “Construction Started on Sumiton Clinic”, Daily Mountain Eagle (Jasper, AL), Wed, Apr 17, 1963, Pages 1–2 Newspapers.com

[39] “Walker Will Get New Plastics Plant”, The Birmingham News (Birmingham, AL), Tue, Nov 5, 1963, Page 1 Newspapers.com

[40] “Kopp Plastics to Begin Work”

[41] Southern Bell Telephone and Telegraph Co., Inc., Jasper, AL Telephone Directory (1963–1966 inclusive), U.S. Telephone Directory Collection, Available Online, Jasper | Library of Congress (loc.gov) Accessed May 20, 2021.

[42] Southern Bell Telephone and Telegraph Co., Inc., Birmingham, AL Telephone Directory (1963–1966 inclusive), U.S. Telephone Directory Collection, Available Online, Alabama | Library of Congress (loc.gov), Accessed May 20, 2021

[43] Government Accounting Office, Procurement Law Division, Bid Protest Decision B-152179, September 24, 1963, https://www.gao.gov/products/b-152179, Accessed June 28, 2021.

[44] Kaufmann, Report on a Management and Operating Study of Pennsylvania Working Home and Philadelphia Association For The Blind, Inc. “The Working Blind”, 16–17.

[45] ibid

[46] “Molded Insulation Co. Marks Three Events”, The Philadelphia Inquirer (Philadelphia, PA), Mon, Mar 8, 1954, Page 25 Newspapers.com

[47] Cobb, M8A1 Scabbards Produced at the Pennsylvania Working Home for the Blind, 6.

[48] NARA/AAD, Records of Prime Contracts ...

[49] Cunningham, U.S. Knife Bayonets & Scabbards, 104.

[50] 1965 and 1967 Annual Reports. Philadelphia, PA: The Working Blind,1965:https://archive.org/details/servicesforblind0000work/page/10/mode/2up?q=%22the+working+blind%22 and 1967:https://archive.org/details/1967annualreport0000work/page/n11/mode/2up?q=%22the+working+blind%22

[51] Kaufmann, Report on a Management and Operating Study of Pennsylvania Working Home and Philadelphia Association For The Blind, Inc. “The Working Blind”, 16–17.

[52] “’Skillcraft’ Products are Blind-Made”, The Wilkes-Barre Times Leader, The Evening News (Wilkes-Barre, PA), Thu, Jul 31, 1969, Page 24 Newspapers.com

[53] “Manufacturer Fears More May Be Less”

© Ralph E. Cobb 2022 All Rights Reserved