| Pictures (click to enlarge) |

Type | Description | Blade Length |

Overall Length |

Muzzle |

Markings | |||

| in. | mm. | in. | mm. | in. | mm. | ||||

|

Colt "New Model" M7 | Bayonet-Knife for use on the Colt-Armalite 5.56 mm. AR–15 assault rifle.

The first of Colt's AR–15 bayonets were made 1961–1962 by Universal Industries of West Haven, CT. They were based on the Second World War M4 bayonet, with a narrow guard and one-piece green or brown plastic grip. Colt assigned them Part No. 62082 in their catalog. While this design was fine for commercial purposes, it had proven unsustainable in U.S. Army service and had been superceded by the M4 Second Production Bayonet in 1954. In 1963, as the U.S. Government became more interested in the AR–15, Colt redesigned their bayonet to better conform to current government specifications. They designated it the "New Model M7" and assigned Part No. 62316 in the Colt catalog. This part number appears on M7 bayonets commercially made for Colt. As shown in this comparison image, Colt's bayonet blade lacked the lightening cuts in the tang area. The hole for the guard securing bar is square (not round) and the blade runout is curved. A few examples with a 90-degree runout have been encountered. As this image reveals, Colt's grips are universal (left same as right) secured with screws and loose hex bolts that fit into hexagons molded into the grips. Colt's scabbard was injection-molded. M.H. Cole indicates “Imperial stated that … the scabbard is made of glass filled nylon [DuPont Nylon 66] with a crinkle type O.D. finish, stamped “U.S. M8A1” and like the bayonet, has no maker mark.” Adding glass to nylon increases its high-temperature strength, wear resistance, and chemical resistance. The roughened finish probably incresed abrasion-resistance. Interestingly, Colt's approach to scabbard manufacture avoided the pitfalls that subsequently plagued the Government's Vietnam-Era M8A1 scabbard production. According to Mr. Robert Roy of Colt Industries, "Part number 62316 is the standard pattern of the M7 bayonet which we have been furnishing since the early 1960's. They have been made by a variety of manufacturers, but in many cases, there are no identifying marks to indicate who the manufacturer is." M.H. Cole indicates that “Imperial [Knife Co.] stated that they made 30,000 of these for Colt.” Mr. Roy also identified Carl Eickhorn Waffenfabrik, in West Germany, as a 1970s producer of Part No. 62316 M7 bayonets for Colt. A quantity of these appeared in 2009, advertised to be new-old-stock 1960s examples. However, it is unclear whether they are 1960s Colt "New Model M7" bayonets or subsequent production by another unidentified manufacturer. |

6.75 | 170 | 11.75 | 295 | .880 | 22.4 | Blade: Colt 'rampant horse' logo, followed by "Colt's 62316," Hartford, Conn USA"

Guard: "U.S. M7" Scabbard: "U.S. M8A1" Glove Fastener: "RAU CO" (partial) |

| U.S. M7 Bayonets | With additional design changes, the Colt "New Model" bayonet (above) was standardized as the U.S. M7 Bayonet-Knife for use with the 5.56 mm. NATO caliber U.S. M16 assault rifle. The M7 bayonet is not just a M4 Second Production bayonet with a larger muzzle ring. The M7 hilt (and grips) are longer than the M4. The M16 rifle's bayonet lug is also wider than that of the M1 Carbine, so the bayonet latch plate dimensions differ accordingly. Procurements began in 1964 and have continued through 2023 (so far). Since 2005, Ontario Knife Co. has been the sole producer.

A total of 30 M7 bayonet production contracts appear to have been let. U.S. government manufacturers and approximate years of production include: An estimated quantity of approximately 4.2 million M7 bayonets have been produced to date. Additional information is also found in the M7 Bayonet Contracts Summary. |

||||||||

| Manufacturer | Description | Markings | |||||||

|

Columbus Milpar & Manufacturing Co. | Milpar was awarded contract DA-11-199-AMC-625 in May 1964, the first U.S. government M7 bayonet contract. Cunningham reported that 93,498 bayonets were delivered under this contract.

Milpar's Fiscal Year (FY) 1966 and 1967 M7 contracts are not well-documented. Four additional contracts awarded to Milpar are believed to be for M7 bayonets. The M7 Bayonet Contracts Summary includes information regarding Fiscal Year 1966–67 Milpar Contracts That Analysis Suggests Were for M7 Bayonets. Cunningham reported 563,530 M7 bayonets produced under Milpar's FY 1966 and 1967 M7 contracts. This quantity is consistent with the amount paid under what are believed to be Milpar's FY 1966 and 1967 M7 bayonet contracts. Characteristic of Milpar's chronic bayonet delivery problems, initial production samples from the May 1964 contract were apparently not delivered until February 1965. Typical of most Milpar M7 bayonets, the example pictured at left exhibits characteristics of Milpar's unique cold-stamping process. The latch plate has a chevron mark unique to Milpar M7 bayonets. The significance of this mark is undocumented, however, it is most likely related to hardness testing. According to Cunningham, the chevron-marked bayonets were “early production.” This has sometimes been misinterpreted by collectors to indicate “first contract.” However, examples observed with the chevron are far too numerous to have been limited to just Milpar’s first M7 contract. |

Guard: "US M7" and "Milpar"

Latch Plate: chevron |

||||||

|

This Milpar M7 has been personalized as a presentation piece.

The blade inscription reads: SGT. JOHN R. ALLGOOD By 1967, Milpar's blade production appears to have changed to a conventional surface-ground blade forming process similar to other contractors; and also began to exhibit a rounded spine. Ca. 1968, Milpar blades began to exhibit what was, in 1968–69, a non-standard curved (or sloped) runout. These features have been erroneously thought to indicate commercial assembly by surplus dealers. However, observation of a Milpar M5A1 bayonet taken from sealed packaging substantiates that the curved (or sloped) runout was used on U.S. government contract production. This example's latch plate also lacks the chevron mark, instead having a more typical hardness-testing dimple. Milpar had production output and quality issues from mid-1966 onwards that culminated in a government-ordered shutdown of bayonet production in January or February 1968. Whittaker Corporation's acquisition of Milpar was finalized almost concurrent to the government shutdown. Significant reworking of the production line appears to have occurred under Whittaker Corp. oversight, followed by Whittaker's replacement of Milpar's bayonet plant supervisors. It is likely that the curved runout was introduced at this point, although the specific production line changes have not been documented. Milpar's manufacturing variations were largely a consequence of their incoherent management of the bayonet production process. While some commercial assembly of bayonets using rejected and surplus Milpar parts did occur, manufacturing variations are not necessarily definitive evidence of commercial assembly or fakery. The bayonet came in an issued M8A1 scabbard that still has the restraining lace. This makes sense given the bayonet’s attribution, as airborne use was the requirement for including a restraining lace on the M8A1 scabbard. |

Guard: "US M7" and "Milpar"

Latch Plate: dimple Blade: (see description) |

|||||||

|

|

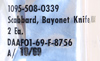

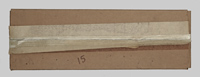

Bauer Ordnance Corp. | Bauer Ordnance Corp. of Warren, Michigan, was awarded contract DAAF01-69-C-0224 in October 1968.

Milpar was the low bidder for this contract, however, federal contracting officials had finally lost patience with Milpar's late deliveries and quality control problems, so awarded the contract to Bauer instead. Cunningham indicates that 1,835,392 bayonets were reportedly delivered by Bauer during FY 1969. This quantity is consistent with the amount paid under this contract. Aetna Tool & Die Co. of Centerline, MI, appears to have produced the blade blanks for Bauer's M7 bayonets. Also at left is an example still sealed in its factory wrapping, with a 12/69 packing date. Note how the cardboard box is ink-stamped with the Defense Acceptance Stamp (DAS). Bauer Ordnance Co. was formed in 1966 by Russell E. Bauer, after leaving his position as president of Cadillac-Gage Co. As president of Cadillac-Gage, it was Bauer who hired Eugene Stoner to develop the Stoner 63 Weapons System. A prolific inventor with nearly 30 patents to his name, he patented a wire-cutter version of the M7 bayonet in 1973. Bauer’s post-Cadillac-Gage business interests were extensive and varied. Bauer Ordnance Co. was acquired by Canoga Electronics Corp. of Chatsworth, CA, in 1969. |

Guard: "US M7" and "BOC"

Wrapper: "1005-073-9238" over "Bayonet, M7" over "1 Each" over "DAAF01-69-C-0224" over "A" Box: Defense Acceptance Stamp and "12/69"

|

||||||

|

This Bauer M7 example is unit-marked, something not officially done in the U.S. The marking is crudely scratched into the blade and on the reverse of the scabbard throatpiece, probably by a unit armorer.

The marking reads “A Co 1/179”. This identifies A Company, First Battalion, 179th Infantry Regiment. The 179th Infantry Regiment has a long history in the Oklahoma National Guard as part of the 45th Division (today, 45th Infantry Brigade Combat Team). The 179th served in both World Wars and the Korean War. During the Second World War, Gen. George S. Patton considered the 45th Division the best Division in the 7th Army, which he commanded during the North African and Sicilian invasions. When the 45th Infantry Division moved to Korea in December, 1951, it was the first National Guard division to go into combat in Korea. It first served in the Yonchon-Chorwon area, and in sectors fronting Old Baldy, Pork Chop Hill, Heartbreak Ridge and Luke's Castle. The 179th also served in Bosnia in 2000 as part of the UN Peacekeeping mission, the Iraqi Surge of 2008; and, subsequently in Afghanistan. The M8A1 scabbard with this example was assembled at the Pennsylvania Working Home for the Blind 1969–70. |

Blade: "A Co 1/179" scratched into blade.

Guard: "US M7" and "BOC" Scabbard: "M8A1" over "TWB" also "A Co" over "1/179" scratched into reverse side of throatpiece. |

|||||||

|

Conetta Manufacturing Co. | Conetta Manufacturing Co. of Stamford, Connecticut, was awarded two M7 bayonet contracts: DA-11-199-AMC-723 in June 1966 and DAAF-01-68-C-0431 in December 1967. Two orders were placed under contract 723 and three orders were placed under contract 0431, totalling $1.306 million.

Cunningham indicates a total quantity of 310,000 from Conetta's two 1966–69 M7 contracts. However, this quantity is unreasonably low for the total amount reported paid. Conetta’s company history was somewhat messy; and here it further clouds the picture. When Conetta’s successor, Dynetics Corp., filed to become a publicly-traded corporation in 1970, it listed an outstanding debt of $323,358 to “repay progress payments from the U. S. Government on government contracts.” There is no record of any government prime contract with Dynetics, so the debt appears to have been inherited from Conetta. During 1965–69, Conetta had contracts for: bayonets, Mark 2 knives, bayonet parts, and other weapons components. We don’t know which contract(s) Conetta may have shorted. Even if the entire outstanding debt inured to M7 deliveries, the quantity delivered would have exceeded 310,000 by a wide margin. |

Guard: "U.S. M7" and "Conetta"

Latch Plate: single punch mark |

||||||

|

Fraser Manufacturing Corp. | Fraser Manufacturing Corp. of Lexington, Michigan, was awarded contract DAAF01-72-C-0188 in October 1971. A second order under this contract was placed in September 1972.

Fraser had hundreds of government contracts and was most well-known for its design and production of vehicle mounts for machine guns. Only one Fraser contract appears to be associated with the M16 rifle, resulting in two orders, both of which I believe are for M7 bayonets. No production quantity has surfaced. However, based on the dollar amount of the orders ($99,000) and the value attributed to M7 bayonets provided to foreign governments in 1971–72 (averaged $2.44 each), the number of bayonets produced appears to be in the neighborhood of 40,000, which explains their scarcity. Manufacturer symbols are assigned by the Department of Defense. FSR had already been assigned to another firm, Fort Smith Rim & Bow Co. of Ft. Smith, AR, so Fraser was assigned FZR instead. A family business founded in 1947 as Fraser Reel and Specialty Co., they primarily manufactured fishing reels in Fraser, Michigan. The mid-1950s were hard times for American fishing tackle makers after tariffs on imported fishing tackle were reduced beginning in 1951. Fraser adapted by relocating to Lexington in 1952 (some sources say 1950, however, their legal filing with the State says 1952). The company broadened its scope to manufacturing of machine shop and metal products, including automobile and boat parts; and sporting goods. The company name was changed to Fraser Manufacturing Corp. in 1963. By the 1970s, 75 percent of Fraser’s production were government contracts. At its peak, Fraser employed approximately 100 workers. Fraser operated until 2013, when the family closed the factory and retired; auctioning off the machinery and donating the building and property to their local school district. |

Guard: "U.S. M7" and "FZR"

Latch Plate: single punch mark |

||||||

|

Imperial Knife Co. | Imperial Knife Co. of Providence, Rhode Island was awarded a total of six M7 bayonet contracts 1973–84.

Imperial Knife Co. of Providence, Rhode Island, was founded in 1914 by brothers Felix and Michael Mirando; and Domenic Fazzano. After Albert Baer purchased Ulster Knife Co. of Ellenville, New York, in 1941, Imperial and Ulster merged in 1942. During the Second World War, Imperial produced M3 knives, M4 bayonets, and many other edged weapons and tools. In 1946, Albert Baer purchased Schrade Cutlery Corp., which also became a division of Imperial. Imperial’s influence on Post-War bayonet development and production is unmatched by any other government contractor. Imperial was active in Post-War bayonet and scabbard design and production for 34 years, from 1952–1986. Michael Mirando helped design the M5 bayonet in 1952 and bring it to production. Imperial was also the first producer of the M4 Second Production bayonet. Imperial produced the M6 bayonet during the 1960s; the M5A1 bayonet during the 1960s and 1970s; and, the M7 bayonet during the 1970s and 1980s. Imperial was the first producer of the M10 scabbard in 1985. Imperial Knife Co. changed its corporate name to Imperial Schrade Corp. in 1984. Imperial Schrade’s M10 scabbard contract appears to be their last U.S. government prime contract. Imperial’s losing out in the M9 bayonet competition resulted in closure of the Providence, RI, plant in 1987. Imperial Schrade continued operations in Ellenville, NY, until its closure in 2004 after 100 years of operation. The company trademarks were purchased by investors, who still use the Imperial and Schrade branding on knives made in China. |

Guard: "U.S. M7" and "Imperial"

Latch Plate: single punch mark |

||||||

|

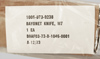

Imperial Knife Co. was awarded its first two M7 contracts in 1973. Production under both contracts appears to have occurred contemporaneously. A total of 361,800 bayonets were reportedly delivered under these contracts. This quantity is consistent with the amount paid under these contracts.

This example is from the first 1973 contract, DAAF03-73-D-1030, with an April 1974 packing date.

|

Inside Label: 1005-073-9238 Plastic Wrapper: 1005-073-9238 |

|||||||

|

This example is from the second 1973 contract DAAF03-73-D-1046, with a December 1973 packing date. | Inside Label: 1005-073-9238 Plastic Wrapper: 1005-073-9238 |

|||||||

|

This example is from the last M7 bayonet contract awarded to Imperial Knife Co.

Contract DAAA09-85-C-0504 was awarded in April 1984. This contract was not identified in Cunningham. This example was packaged in December 1984. The quantity produced has not been found. Based on the $240,000 paid under this contract, the quantity was likely in the 35,000–40,000 range. The white substance seen in images of the bayonet is a preservative applied when the bayonet was packaged. The curved edge runout seen in images at left is typical of later Imperial M7 bayonet contracts.

|

Label (wrapper):

"1005-00-073-9238 Carton: A 12/84 Guard: "US M7" and "Imperial" |

|||||||

|

General Cutlery, Inc. | General Cutlery, Inc. of Fremont, Ohio, was awarded three M7 bayonet contracts. General Cutlery was also a M7 bayonet subcontractor for Lan‑Cay Inc. (see below).

A feature of General Cutlery M7 bayonets is that the factory edge is often more heavily ground than on bayonets from other contractors. The edge is visible on this example that was removed from sealed packaging to be photographed. General Cutlery was founded ca. 1945. In 1950, the company was purchased by Carleton Reitz and two partners, becoming the firm as we know it. His son, David, worked at the company, and served as owner/president following the passing of Carleton Reitz in 1999. The company was small, typically 10–20 employees. The plant where M7 bayonets were manufactured was a former rural elementary school campus west of Fremont, Ohio, that General Cutlery purchased in 1982 and converted into a factory. Primarily a producer of kitchen knives, the plant, equipment, and workforce were geared toward manufacturing at a level of commensurate with the M7 bayonet. When Lan Cay subcontracted its M9 blade production to General Cutlery in 1992, the M9 blade and its more exacting manufacturing standards proved beyond the plant’s capability. Following their production of government-contract M7 bayonets, General Cutlery sold bayonets and knives commercially. They also are reported to have supplied upwards of 5,000 refurbished bayonets used by military honor guards. General Cutlery still appears to own the Fremont factory. A photographic survey of the plant in 2019 showed evidence of activity, while a more recent 2022 survey did not. In 2023 the company’s status changed to permanently closed. |

Guard: "U.S. M7" and "Gen Cut" | ||||||

|

This example is from the first M7 bayonet contract awarded to General Cutlery. Contract DAAA09-85-C-0540 was awarded in March 1985.

Cunningham reported quantity of 45,800. However, the quantity is too low for the $502,000 paid under the contract, so this must have been a partial report. The true quantity produced under this contract is likely more in the neighborhood of 75,000. |

Label:

"1005-00-073-9238 |

|||||||

|

This example is from the second M7 bayonet contract awarded to General Cutlery, contract DAAA09-87-C-0931.

This contract was not known until 2022, when the example pictured at left turned up in sealed packaging. No record of this contract exists in federal government contracting databases. I made an inspection slit in package to verify the manufacturer. The quantity produced under this contract is unclear. |

Label:

"1005-00-073-9238 |

|||||||

|

This example is from the third M7 bayonet contract awarded to General Cutlery. Contract DAAA09-88-C-0366 was awarded in January 1988.

Cunningham reports various figures for the delivery quantity: 24,400; 56,801; and 81,201 (sum of the first two). 56,801 is consistent with amount paid, so is likely correct.

|

Label:

"1005-00-073-9238

|

|||||||

|

Lan-Cay Inc. | Lan‑Cay Inc. of Carrolton, KY, is well known for its production of the M9 Bayonet. However, Lan‑Cay was also awarded two contracts for the M7 bayonet. Lan‑Cay had no cost-effective way to produce M7 bayonets, so subcontracted production to General Cutlery Co. The resulting bayonets are marked "Gen Cut" just like those produced by General Cutlery during the 1980s.

Frank Trzaska and William Humes first reported, ca. 2000, that Lan‑Cay, was awarded small contracts for the M7 Bayonet and M10 Scabbard in 1998. Lan‑Cay was awarded contract DAAE20-98-P-0241 in May 1998. At only 1,287 bayonets, it is the smallest known U.S. Government M7 bayonet prime contract. Lan‑Cay accepted this contract (and another for M10 scabbards), four weeks after the government exercised a pending $246,000 contract option enabling Lan-Cay to continue producing M9 bayonets. Note how the label printed on the plastic wrapper has General Cutlery's CAGE Code, 20014; and the adhesive label below has Lan‑Cay’s contract number. |

Label:

"1005-00-073-9238 |

||||||

|

Lan‑Cay was awarded contract W52H09-06-C-0002 in November 2005. The existence of this contract was not recognized until examples in original packaging surfaced in 2023. Up to now, the only recognized producer of the M7 Bayonet/M10 Scabbard Combo (National Stock Number 1095-00-017-9701) has been Ontario Knife Co. These findings change that.

The contract amount was $257,987, which suggests that the quantity produced was in the neighborhood of 12,000. At $257,987, the contract required competitive bidding but the government justified awarding it to Lan‑Cay on a sole-source basis due to “urgency.” This urgent contract was supposed to be completed in six months (by May 2006). General Cutlery required two delivery extensions until November 2008, taking three years to complete the order. This may help explain why, since 2005, Ontario has been the government’s sole supplier of M7 bayonets and M10 scabbards. Note how the package label has Lan‑Cay’s contract number along with General Cutlery's CAGE Code, 20014. |

Carton Label:

"1095-00-017-9701 Bayonet Package: "1005-00-073-9238 |

|||||||

|

Ontario Knife Co. | Ontario Knife Co. of Franklinville, New York, has been awarded six prime contracts involving the M7 bayonet. In addition, Ontario has been subcontracor on three more M7 bayonet procurements. Ontario's contracts sometimes include M10 scabbards, either packaged together with the M7 bayonet or packaged separately. Ontario has been the Government's sole source of M7 bayonets since 2005, with its most recent production run occuring in 2023.

This example is from the first bayonet contract awarded to Ontario Knife Co. in October 1987. Contract DAAA09-88-C-0129 was also the first contract providing for a new-made M7 bayonet and M10 scabbard packaged together. 58,100 bayonets were reportedly delivered under this contract 1987–88. This quantity is consistent with the amount paid under this contract. These were catalogued under NSN 1005-00-017-9701: Bayonet-Knife M7 with Scabbard. This NSN applies regardless of the scabbard type packaged with a M7 bayonet. It has been used since the 1970s on repacks of existing M7 bayonets that combined the bayonet and a M8A1 scabbard into a single carton. Ontario Knife Co. was founded in Naples, NY, in 1889, taking its name from the county where it was founded. The firm moved to Franklinville, NY in 1902. The company was purchased in 1967 by Servotronics, who has since served as Ontario’s parent company. In addition to developing a huge catalog of commercial knives, Ontario became the primary producer of edged weapons for the U.S. Government during the post-9/11 period. Ontario amassed over 600 prime contracts since 2008, including the: M7 bayonet; M10 scabbard, M9 bayonet; OKC3S bayonet; and, a variety of combat knives, survival knives, and other edged tools. Servotronics is primarily a manufacturer of servo controls and other high technology products used in aircraft, jet engines, missiles, manufacturing equipment. In a strategic move, Servotronics determined to divest its consumer products group of which Ontario Knife Co. was a part. By 2023, there were 56 employees remaining at the Franklinville plant. Blue Ridge Knives, one of Ontario’s existing wholesale distributors, purchased the company for $2.1 billion at the end of July 2023 and immediately closed the Franklinville plant, ending its 121 years of operation. As Ontario has been the government’s sole source of bayonets and scabbards since 2005, their closure leaves a significant void to be filled going forward. |

Label:

1005-00-017-9701 Guard: "U.S. M7" and "Ontario" |

||||||

|

This example is from the second run that Ontario Knife Co. produced of the M7 Bayonet/M10 Scabbard combo.

Sealed in its factory wrapping are both the M7 bayonet and a black M10 scabbard. Contract W52H09-06-D-0068 was awarded in 2006. It was a massive indefinite-delivery contract that included M7 bayonets, M10 scabbards, the M7/M10 combo, M9 bayonets, and various spare parts for the M9 system. The M7/M10 combo was made 2006–10 under this contract, with a total of 90,000 delivered. This example was made in 2009. |

Label:

"1095-00-017-9701 |

|||||||

|

This example is from the last M7 bayonet prime contract awarded to Ontario Knife Co. More recent contracts were fulfilled by Ontario via a middleman who served as prime contractor.

Contract SPM7L1-11-M-D867 was awarded in August 2011. This contract was for the M7 bayonet without scabbard. 3,746 bayonets were delivered under this contract. This example was packaged in October 2011. |

Label:

"1095-00-017-9701 |

|||||||

| M7 Bayonet w/Scabbard Repacks | During the 1970s and 1980s, the U.S. Government repackaged existing stocks of unissued M7 bayonets with an unissued M8A1 scabbard. National Stock Number (NSN) 1005-00-017-9701 was assigned to catalog these as: Bayonet M-7 w/Scabbard.

The bayonets are typically found sealed in their original packaging. M8A1 scabbards were packaged in pairs, so these were removed from their original packaging, wrapped individually in a piece of brown Kraft paper, and inserted into a cardboard carton with the bayonet. Bayonets observed from these packages have been mostly from Bauer Ordnance Corp. and Imperial Knife Co. Scabbards are mostly PWH and TWB, with a few of the earlier makers encountered. Some of the labels feature the European spelling "Bajonet," suggesting that some of the repackaging work may have been contracted out to firms there. |

Label:

1005-00-017-9701 |

|||||||

| Pictures (click to enlarge) |

Type | Description | Blade Length |

Overall Length |

Muzzle |

Markings | |||

| in. | mm. | in. | mm. | in. | mm. | ||||

|

Commercial Milpar Knife | This commercial knife was assembled from leftover or rejected Milpar bayonet parts.

The blade and plate are from a Milpar M5A1 bayonet and the guard is from an M7. The grips are copies of U.S. M5A1 grips, but were molded without a cut-out for the latching lever. The plastic molder copied everything, including the part numbers and original mold marks. The blade is ca. 1968 Milpar and rough, almost certainly a reject. The guard is unsecured, held in place only by the grips. A surplus dealer reportedly purchased a quantity of bayonets, plus the remaining bayonet parts after closure of the Milpar plant. Milpar also experienced high rejection rates 1966–68. The New Lexington, Ohio, bayonet plant was small and very cramped, which likely forced them to dispose of rejected parts locally well before the plant's closure. This example is obviously a product of commercial assembly by a surplus dealer. However, claims that many post-war bayonets found today are assembled by surplus dealers have been vastly overblown. Unless there are obvious signs of commercial assembly, collectors will be right far more often if they presume that post-war bayonets are legit. |

6.75 | 170 | 11.50 | 290 | .880 | 22.4 | Guard: "US M7" and "Milpar" |

|

Commercial M7 Bowie | This commercial bayonet was inspired by an experimental bayonet considered during the Vietnam War which was not adopted.

It marries a U.S. Navy Mk. 2-style clip-point blade with a M7 bayonet crosspiece and latch plate assembly. Examples are found with both stacked leather and plastic grips. According to Frank Trzaska, they were assembled by New Jersey (today, Pennsylvania) surplus dealer SARCO, Inc., using parts they purchased from Conetta's liquidation sale. Although a very cool-looking bayonet, these are neither rare, experimental, military, nor worth big bucks. |

6.875 | 175 | 11.75 | 300 | .880 | 22.4 | Ricasso: "U.S." over "Conetta" |

|

U.S. Army M7 Training Aid | Plastic training aid bayonet used by the U.S. Army at Ft. Benning, GA.

Comprised of a crude casting of a M7 Bayonet-Knife hilt and crosspiece with a thick, rounded plastic blade. There is no mortise cast into the pommel, so it cannot be fixed to a rifle. Consequently, it was most likely used for training soldiers how to disarm a knife-wielding assailant. The muzzle ring is broken, which suggests that this example has seen some rough use. Devices Fabrication is the U.S. Army entity responsible for the design and fabrication of training devices such as pugil equipment, targets, rubber ducks (e.g., M4, M16A2, M240B, M60, M249), Improvised Explosive Device (IED) training aids, fox hole stands, weapon mock-ups, and many other devices. There were four Army-wide fabrication sites: Fort Benning, GA; Fort Gordon, GA; Fort Jackson, SC; and Fort Knox, KY. TAD-066 was the official U.S. Army training aid designation for "Bayonet, Plastic." This example was made at the U.S. Army Training Support Center (TSC), Sand Hill, Fort Benning, GA, according to the provenance that accompanied it. |

6.50 | 165 | 11.25 | 286 | .870 | 22.1 | Blade: "Device Shop TAD-066A" |

| Post-War M8A1 Scabbards | Post-War M8A1 scabbard production occurred briefly during the mid-1950s and then ran almost continuously from 1961-70.

Many M8 scabbards were modified with the M8A1 strap assembly during the mid-1950s. The Korean War and foreign distributions under the Military Assistance Program depleted existing stocks of M8A1 scabbards. Distribution of the M5 bayonet in early 1954 created a necessity for some units receiving M5 bayonets to modify M8 scabbards as a stopgap measure. Local approaches to modification resulted in the variations encountered today. The original markings were left alone, because surface grinding would excessively weaken the sheet steel fitting. Once modified, scabbards were designated M8A1 regardless of the marking. Victory Plastics Co. was the sole producer of M8 and M8A1 scabbards from 1943–1961. The history of Beckwith Manufacturing Co., Victory Plastics Co., and their scabbard production has been well-documented by authors/researchers, Gary Cunningham and Frank Trzaska. Gary’s research can be found in his books and findings of both on Frank Trzaska’s great site, http://usmilitaryknives.com. My research (below) adds a few more details regarding their post-War production. Vietnam War Era M8A1 scabbard producers and their production has been a less well understood area that has posed significant challenges to researchers due to lack of available federal contract data covering the first half of the 1960s. It has been a long struggle to document who the producers were, in what time frames they made their scabbards, and what their respective manufacturing processes entailed. As with any story that is pieced together over time, there have been advances, as well as errors, made along the way. Some unanswered questions still remain. However, as of 2021, a relatively clear and coherent chronology has finally emerged. The two- or three-letter codes found on Vietnam-Era M8A1 scabbards are known in the Department of Defense (DOD) as “Manufacturer Symbols.” These are unique identifiers officially assigned by DOD to certain types of contractors. M8A1 Scabbards produced during the Vietnam War Era are found with the following manufacturer symbols: PWH, TWB, VIZ, VIZ/WD, and WD. U.S. government prime contractors, their manufacturer symbols, and approximate years of production include: —Viz Manufacturing Co.: VIZ 1962–63 Details and supporting evidence regarding production at the Pennsylvania Working Home for the Blind can be found in my article: M8A1 Scabbards Produced at the Pennsylvania Working Home for the Blind (ref. SABC Journal Volume 91, Spring 2015). Details and supporting evidence regarding production at Wilson-Duggar Co. and Viz Manufacturing Co. can be found in my article: 1960s U.S. Scabbards Produced by Viz Manufacturing Co. and Wilson-Duggar Co. (ref. SABC Journal Volume 121, Fall 2022). The following high-level synopsis reflects these findings and summarizes what has been documented regarding production of Post-War M8A1 scabbards. Additional information is available in the Post-War M8A1 Scabbard Contracts Summary. The following are examples of Post-War M8A1 Scabbards. See Second World War M8 and M8A1 Scabbards for additional information on wartime M8 and M8A1 scabbards. |

||||||||

| Manufacturer | Description | Markings | |||||||

| 1950s Contract

1961 Contract |

Victory Plastics Co. | During the 1950s, Victory Plastics manufactured M3, M7, and M8A1 scabbards. Victory Plastics' first Post-War M8A1 scabbard production contract has long been attributed to 1953. Recent discoveries found documentation of two scabbard contracts awarded to Victory Plastics during this period:

1) Fiscal Year 1953: A $220,000 contract for “scabbards” awarded in September 1952 with an initial delivery date of March 1953. It is not documented whether this contract included M8A1 Scabbards. Packaging has been observed of M7 scabbards with July and August 1953 packing dates under contract DA-19-020-ORD-2905. 2) Fiscal Year 1954: A $155,560 contract for "M8A1, scabbard, bayonet, knife" awarded sometime during January-June 1954. Victory Plastics Co. was also awarded a research & development contract, DA-19-020-ORD-2399, which led to a September 1954 final report titled “M-8 Fiberglass Scabbard for M-4 Bayonet Knife, Project TS2-2028.” TS2-2028 was a Springfield Armory project related to continued development of the lightweight .30 cal rifle (i.e., the M14). This contract was likely the research & development that led to the M8A1 scabbard design changes observed on Post-War M8A1 scabbards. The 1950s scabbards differed from wartime M8A1 scabbards in only small details. However, Cunningham indicates that a design change was implemented mid-contract during 1950s M8A1 production to increase the amount of offset between the belt strap assembly (belt hanger) and scabbard body, by lengthening the steel top plate flange. This was done to better accommodate the M5 bayonet’s wider crosspiece. The manufacturer’s mark used on Victory Plastics' Post-War scabbards was “V.P. Co.”, instead of “B.M. Co.” The 1955 merger creating Beckwith-Arden Inc. legally terminated the existence of Beckwith Manufacturing Co. This required discontinuance of the "B.M. Co." marking, a fact which would have been known internally by 1954 when the documented M8A1 scabbard contract was signed, even if it were not yet public knowledge. Whether this would have been so in September 1952 is less certain, casting some doubt as to whether the first contract included M8A1 scabbards (or if it did, how they were marked). Following completion of their 1950s scabbard production, the machinery and tooling was stored on-site at the Victory Plastics plant and kept in working order at government expense. This was part of a Post-Korean War government program to ensure that ordnance items could be more rapidly brought to production should the need for rapid mobilization of troops occur again. Victory Plastics was again awarded a M8A1 Scabbard production contract in January 1961. The 1961 scabbards incorporated the metal tip protector and reversal of the hilt strap arrangement. Scabbard bodies from this contract were also marked on the reverse with the Defense Acceptance Stamp (DAS) in black ink using a ½-inch rubber stamp. Victory Plastics also manufactured M1917 scabbards 1962–63, however, lost out in two successive M8A1 scabbard procurements: to Viz Manufacturing Co. in August 1962 and Wilson-Duggar Co. in July 1963. The October 1964 death of Harry H. Beckwith thrust Victory Plastics President, Edwin L. Beckwith, into overall responsibility for Beckwith-Arden Inc. and all of Beckwith’s subsidiaries. Victory Plastics closed, followed by the 1965 sale of its plastic molding machinery and building. |

1950s Contract

Example

Throatpiece: "U.S. M8A1" over "V.P. Co." Top Plate (underside): Vp 4" Body (reverse): "Vp 31" 1961 Contract Example Throatpiece: "U.S. M8A1" over "V.P. Co." Top Plate (underside): Vp 8" Body (reverse): "Vp F" and DAS stamp |

||||||

| Viz Manufacturing Co., Inc. | The firm we know as Viz Manufacturing Co. was a highly sought-after Philadelphia, PA, government contractor who also manufactured electronic weather instruments and sensitive electronics used in munitions. The company's name was actually Molded Insulation Co., Inc. from 1932, when Victor I. Zelov acquired it from the Bendix Corp., until 1965, when he formally changed the corporate name to Viz Manufacturing Co., Inc.

Viz Manufacturing Co. of was the immediate successor to Victory Plastics Co., producing M8A1 scabbards during 1962–63 (contract DA-11-199-ORD-728). In 2020, original manufacture heat-sealed cellophane packages containing VIZ M8A1 scabbards labeled with an August 1962 contract date and March 1963 packing date were discovered by collector/researcher Boyd M. Jenkinson, Jr., conclusively proving that Viz Manufacturing Co. produced M8A1 scabbards much earlier than was previously understood. Insufficient data exists to estimate how many M8A1 scabbards that Viz Manufacturing Co. produced. The estimate published in my 2015 article of 50,000 is likely too low (and should now be considered erroneous). This figure was based on Viz Manufacturing Co’s 1969 scabbard contract, which has since been proven to have been for plastic M1917 bayonet scabbards. Although Viz only produced M8A1 scabbards 1962–63, it appears that Viz and its owner, Victor I. Zelov, continued to influence M8A1 scabbard production until the last government-contract M8A1 scabbard was produced in 1970. Zelov maintained a self-imposed ceiling of 498 employees to ensure Viz Manufacturing’s eligibility for small-employer federal contracting preferences. This self-imposed workforce ceiling would later constrain M8A1 scabbard production, likely contributing to adoption of the M10 scabbard. Completed M8A1 scabbards were packaged in pairs, encased in a heat-sealed cellophane wrapper, which was placed inside a cardboard carton. The sealed package pictured at left is badly yellowed, suggesting that the cardboard carton has been absent for a long time. Viz also produced two types of plastic machete sheaths 1966–67 and plastic M1917 bayonet scabbards 1969–70. Bureaucratic inconsistencies resulted in creation of a new federal contractor identity for “Viz Mfg. Co.” well before the 1965 corporate name change; and the continued letting of new federal contracts under the company’s “Molded Insulation Co. Inc.” identity as late as June 1967. The concurrent use of two contractor identities likely enabled the symbol VIZ to be used on M8A1 scabbards in 1962–63, instead of the (Molded Insulation) company’s officially-assigned manufacturer symbol ML. When the company formally changed its name to Viz Manufacturing Co., in 1965, DOD found that another firm, Curtis Mfg. Co. - Visioneering-Bunnel Division, of Cleveland, OH, was already assigned the symbol VIZ. Eventually, VZM was assigned as Viz Manufacturing Co’s. manufacturer symbol. This is how VZM came to be used on M1917 scabbards and machete sheaths. |

Label:

1095–508–0339-B008 Throatpiece: "VIZ" |

|||||||

|

|

Wilson-Duggar Co., Inc. | This manufacturer’s identity was a mystery for decades until it was re-discovered in 2021. Wilson-Duggar Co. of Jasper, AL, was formed in 1961 to manufacture magnetic toy building blocks. Factory construction in Dora, AL, was financed with federal redevelopment loans to the local government, who would own the factory and its machinery, then lease it to Wilson-Duggar Co.

Wilson-Duggar Co. was awarded a contract to produce M8A1 scabbards on July 12, 1963, prevailing over both Viz Manufacturing Co. and Victory Plastics Co. Wilson-Duggar Co. produced M8A1 scabbards in 1964, possibly into 1965. Unbeknownst to the federal government, by the time the factory was completed in, June 1963, the company had already run out of money and was unable to begin manufacturing operations. In November 1963, a group of Birmingham industrialists were brought in as fixers to take over Wilson-Duggar factory operations and produce the scabbards. The contract was for a minimum quantity of 144,415 scabbards. However, insufficient data exists to estimate how many scabbards that Wilson-Duggar Co. actually produced. The manufacturer symbol used by Wilson-Duggar Co. was WD. However, some (if not all) Wilson-Duggar Co. M8A1 scabbards were apparently assembled using externally-supplied subassemblies (steel throatpieces and plastic scabbard bodies). These included leftover subassemblies from Victory Plastics Co. (whose factory closed in 1964) and subassemblies supplied by Viz Manufacturing Co. This is explained by some WD-marked scabbards having subassemblies with Victory Plastics Co. markings (the ‘Vp” mark on the underside of the steel top plate and “Vp” mold mark on the reverse of the plastic body), while others are found with a “VIZ/WD” marking where the “WD” was apparently added to an existing VIZ-marked throatpiece. It is unclear whether or not Wilson-Duggar Co. ever manufactured their own subassemblies. Wilson-Duggar Co’s. disappearance shortly after scabbard production began at the Pennsylvania Working Home for the Blind suggests that they likely never did. It is well-documented that the Pennsylvania Working Home consumed all of the plastic scabbard bodies that could be externally-supplied and would have utilized even more if they were to be had. If Wilson-Duggar Co. had manufactured its own subassemblies, both factories could have produced scabbards concurrently. Instead, by 1966 Wilson-Duggar Co. was apparently defunct. |

Upper Example

Throatpiece: "U.S. M8A1" over "WD" Top Plate (underside): V:p9" Body (reverse): "Vp" over "E" Lower Example Throatpiece: "U.S. M8A1" over "VIZ/WD" |

||||||

|

|

Pennsylvania Working Home for the Blind | The Working Home was the final prime contractor for M8A1 scabbards 1965–1970, assembling approximately 4 million scabbards.

The Working Home operated from 1874–1979, as a sheltered workshop that provided employment for visually-impaired people. Sheltered schools and workshops were common until social policy was changed to integrate people with disabilities more fully into the community. Two different manufacturer symbols were used by the Working Home: PWH was used 1965–68. Several variations of this mark exist. TWB was used on the Working Home's final scabbard contract, 1969–70, after their corporate name change to: The Working Blind, Inc. The Working Home only fabricated the Belt Strap Assembly, then assembled scabbards using externally-supplied subassemblies. Hard evidence is lacking regarding who supplied the Working Home’s subassemblies. However, circumstantial evidence consistently points to Viz Manufacturing Co. as the likely supplier. For example, Viz Manufacturing Co. had supplied some of the subassemblies used by the Working Home's immediate predecessor, Wilson-Duggar Co.; the Working Home was located only 9 miles from Viz Manufacturing Co.; and, the owner of Viz Manufacturing Co., Victor I. Zelov, served on the Working Home's Board of Managers from 1965 thru at least 1967. In 1967, the Working Home’s M8A1 scabbard output was 108,000 per month. The government needed 150,000 scabbards per month, however, the Working Home’s output was limited by the availability of plastic scabbard bodies. Viz Manufacturing was a highly-sought after defense contractor with a lengthy backlog of electronics orders. Allocating additional resources to production of scabbard components was problematic, as doing so would adversely impact other Viz defense contract deliverables. By mid-1969, the Working Home’s monthly M8A1 scabbard output had reached 125,000, however, 150,000 proved unattainable. Expected completion of the Working Home's final contract was May 1970. Two months earlier, on March 16, 1970, the M10 Scabbard was adopted. No evidence of further U.S. Government M4–M7 bayonet-knife scabbard production has been found until the first M10 scabbard contract was let in 1985. From 1965–68, the Working Home packaged their scabbards similar to Viz Manufacturing Co. The cartons pictured at left each contain two M8A1 scabbards assembled at the Pennsylvania Working Home in 1968. One carton remains sealed, never having been opened since leaving the Working Home's shipping department more than 50 years ago. The open carton reveals two scabbards inside a heat-sealed cellophane wrapper. This packaging has proven quite effective. Other than some verdigris around the brass rivets and glove fastener, the scabbards remain perfectly preserved after more than 50 years in storage. The cardboard carton was produced in Bala Cynwyd, Pennsylvania, a town on the western edge of Philadelphia founded by Welsh settlers in the 1680s. Scabbards from the final, 1969–70, Working Home contract were packaged differently than earlier contracts. No longer sealed in a cellophane wrapper inside a cardboard carton, the two scabbards are in a foil-lined Kraft Paper wrapper, sealed inside a polyethylene outer package. |

Sealed Box

Box Label: 1095–508–0339 Open Box Cellophane Wrapper Label: 1095–508–0339 Throatpiece: "PWH" Poly Wrapper Label: 1095–508–0339 Throatpiece: "PWH" or "TWB" |

||||||

|

Replacement M8A1 Scabbard Restraining Lace | The "leg-tie" accompanying the M8A1 Scabbard is often erroneously thought to be a boot lace. However, the scabbard restraining lace is officially cataloged under Weapons, Federal Supply Class (FSC) 1005. Boot laces are cataloged under Shoe Findings and Soling Materials (FSC 8335).

Official Second World War M8A1 Scabbard drawings refer to it as the "thong." The same terminology was already in use to describe a similar item on the M1916 Holster. New scabbards included a leather thong. As shown in official drawings, it is unclear whether or not the scabbard thong was unique or was the same thong used with the M1916 Holster. When Post-War M8A1 Scabbard changes were adopted during the mid-1950s, the material was changed from leather to olive green fabric. It was catalogued as "Lace, Restraining, Scabbard"; Federal Stock Number (FSN) 1005-300-5378; Part No. 7267136. The fabric restraining lace is 52 in. (1.32 m.) long. Replacement restraining laces were packaged as single laces. The M8A1 restraining lace pictured at left was made in November 1970. Use of the restraining lace was continued with the M10 Scabbard, however, in black rather than olive green. No information on production of olive green restraining laces has been identified. Approximately 115,000 black replacement restraining laces appear to have been procured 1986–88 following commencement of M10 Scabbard production. The restraining lace's FSN, 1005-300-5378, was also assigned to the leather lace used to secure the cheek pad to the M1D Sniper Rifle's stock. At some point, Part No. 7267136 also became associated with the M1916 Holster, as the "Lace, Restraining". The details around these apparent overlaps are not known. |

Label:

"1005-300-5378 |

||||||

| M10 Scabbards | The Bayonet-Knife Scabbard M10 was assigned Federal Stock Number (FSN) 1095-223-7164 on March 16, 1970, as the final M8A1 Scabbard contract was being completed. (The FSN was subsequently revised to National Stock Number (NSN) 1095-00-223-7164 before any M10 Scabbards were produced.)

During the Vietnam War, the government encountered difficulties around production of M8A1 scabbards, much of which was related to its glass-reinforced plastic scabbard body. Despite professing to be a molded plastics factory, Wilson-Duggar Co. apparently proved incapable of manufacturing M8A1 scabbard bodies. Victory Plastics Co. lost out in successive M8A1 scabbard procurements, contributing to its closure; and, sale of its plastic molding machinery and building. This left Viz Manufacturing Co. as the apparent sole producer of M8A1 scabbard bodies. Viz Manufacturing Co’s. limited capacity for production of cloth-reinforced scabbard bodies subsequently became a wartime constraint on production of M8A1 scabbards. The M10 Scabbard body took advantage of newer high-strength polymers that enabled manufacture by injection-molding. U.S. government contract scabbards are molded of black plastic (other colors are commercial production). The Belt Strap Assembly is made from common black nylon webbing. It is entirely of sewn construction, save for the snap on the hilt strap. The M10 Scabbard includes a “restraining lace,” proper term for what collectors often refer to as the “leg tie” or “boot lace.” It is the same 52-inch length as was used with the M8A1 Scabbard, but in black rather than olive green. M10 scabbard components are, essentially, commodities. Production can easily be scaled to whatever quantity is required without encountering difficulties in obtaining specialized components, as had occurred with the M8A1 scabbard. The M10 Scabbard was both less expensive to manufacture and reduced maintenance costs. The last M8A1 Scabbards produced cost $1.60 each. Adjusted for inflation, this corresponds to approximately $4.57 in October 1986, when the acquisition cost for the M10 Scabbard was $2.78. Unlike the M8A1 Scabbard, the M10 Scabbard was, essentially, non-repairable. The only replaceable part was the Restraining Lace. When found to be unserviceable (e.g., crack > ½ in.; cut or tear in strap > ¼ in., or defective snap), it was simply discarded. Although adopted much earlier, the first contract for M10 scabbards was not awarded until 1985. Commercial And Government Entity (CAGE) Codes appearing on M10 scabbards, and approximate years of production include: —Imperial Schrade Corp.: 1985–86 (CAGE 74846) Imperial Schrade Corp., General Cutlery, Inc., Lan-Cay Inc., and Ontario Knife Co. are well-known bayonet makers. Hauser Products, Inc. was a Chicago, Il, plastics firm. Ontario has been the sole source of M10 scabbards since 2009. Some M10 Scabbards bear an additional CAGE Code, 19204, representing US Army, Rock Island Arsenal, IL, the government agency overseeing the procurement. 8448476 is the official part number assigned to the M10 Scabbard. To date, approximately 230,000 individually-packaged M10 Scabbards appear to have been produced under U.S. government contracts. An additional approximately 175,000 M10 Scabbards appear to have been produced in conjunction with government contracts for the M7 Bayonet/M10 Scabbard combo. Production has occurred as recently as 2020, leaving open the possibility of further procurements. Additional information is available in the M10 Scabbard Contracts Summary. A variety of commercial M10 Scabbards have also been produced. |

||||||||

| Manufacturer | Description | Markings | |||||||

|

Imperial Schrade Corp. | Imperial Schrade Corp. of Ellenville, New York, was awarded the first M10 Scabbard contract, DAAA-09-85-C-1316, in November 1985. An additional order was placed under this contract in February 1986. Cunningham reported a total of 112,400 produced by Imperial in his 1996 book. This quantity is consistent with the total amount paid under the contract, so appears correct.

Hauser Products, Inc. was low-bidder for this contract, but their bid was rejected on a technicality, per the Government Accountability Office (GAO). Imperial Knife Co. changed its corporate name to Imperial Schrade Corp. in 1984. Imperial Schrade’s M10 scabbard contract appears to be their last U.S. government prime contract. Imperial’s losing out in the M9 bayonet competition resulted in closure of the Providence, RI, plant in 1987. Imperial Schrade continued operations in Ellenville, NY, until its closure in 2004 after 100 years of operation. The company trademarks were purchased by investors, who still use the Imperial and Schrade branding on knives made in China. |

Scabbard:

"M10" and "19204 ASSY 8448476" over "MFG 74846" Label: 1095-00-223-7164 |

||||||

|

Hauser Products Inc. | Hauser Products Inc. of Chicago, IL, was a plastics molding firm that operated in the Chicago, IL, area from 1946–2000.

Hauser Products was awarded contract, DAAA09-87-C-0130, in October 1986. Cunningham reported a total of 33,500 produced by Hauser in his 1996 book. This quantity is consistent with the total amount paid under the contract. In 1998, Hauser Products produced M10 Scabbards as a subcontractor for Lan‑Cay Inc. under contract DAAE20-98-P-0221. According to M7 Bayonet specialist William Humes, 10,700 scabbards were produced under this contract. This quantity is consistent with the total amount paid under the contract. |

Scabbard:

"M10" and "19204 ASSY 8448476" over "MFG 1Z803" Label: 1095-00-223-7164 |

||||||

|

General Cutlery Co. | General Cutlery Co. of Fremont, Ohio, was awarded its first M10 Scabbard contract, DAAE20-96-C-0224, in May 1996.

General Cutlery had three subsequent sole source purchase order contracts during fiscal years 2000 and 2002, none of which were reported to the National Archives, suggesting that these were likely small contracts under $25,000 each. The number of scabbards produced under General Cutlery's three contracts is not known. General Cutlery is also associated with M10 Scabbards supplied with their 1991 Australian M7 bayonet production; with the Lan‑Cay M7 Bayonet/M10 Scabbard combo; and, with a variety of M10 Scabbards produced commercially. Evidence suggests that Hauser Products may have manufactured all of the scabbards associated with General Cutlery Co., including government contract scabbards bearing General Cutlery Co's. CAGE Code. As shown in this comparison image, scabbards bearing Hauser's and General Cutlery Co's CAGE Codes both have the markings recessed below the surface in a similar font. (Scabbards by Imperial and Ontario have raised markings and use a different font.) |

Scabbard: "M10" and "19204 ASSY 8448476" over "MFG 20014"

Label: 1095-00-223-7164 |

||||||

|

Lan-Cay Inc.

Red-Thread M10 Scabbard |

Rare “red-thread” M10 scabbard, with a single red thread running along the left side of the black nylon belt hanger.

Lan-Cay Inc. of Carrolton, Kentucky, was awarded contract, DAAE20-98-P-0221, in April 1998. 10,700 scabbards are believed produced under this contract. The scabbards were produced by Hauser Products Inc. and bear their CAGE Code. However, the package label with Lan-Cay's contract number bears the General Cutlery CAGE Code. This suggests that Lan-Cay may have subcontracted to General Cutlery, who then retained Hauser to do the work. The red-thread scabbards came from this production run, as an example in sealed packaging, labeled as indicated above, was discovered ca. 2000. In all likelihood, the red thread was an end-of-roll warning intended to prompt the sewing machine operator fabricating and attaching the strap assembly to stop production and replenish the spool of nylon webbing. It is unknown how many had the red thread or why government inspectors accepted these. |

Scabbard (throat): "M10"

Scabbard (body): "19204 ASSY 8448476" over "MFG 1Z803" |

||||||

|

Lan-Cay Inc. was awarded contract, W52H09-06-C-0002, in November 2005. The M10 Scabbard was a component packaged along with M7 Bayonets produced by General Cutlery Inc. Approximately 12,000 are believed to have been produced under this contract.

The scabbards were likely produced by Hauser Products Inc., however, bear General Cutlery's CAGE Code. The outer carton label with Lan-Cay's contract number bears the General Cutlery CAGE Code, as do the printed labels on both the bayonet and scabbard wrappers. This suggests that Lan-Cay may have subcontracted to General Cutlery, who assembled the bayonets but retained Hauser to make the scabbards. |

Carton Label:

"1095-00-017-9701 Scabbard Package: "1005-00-073-9238 |

|||||||

|

Ontario Knife Co. | Ontario Knife Co. of Franklinville, New York, was awarded six prime contracts between 1987–2011 that included M10 scabbards.

Procurements resumed in 2018 via a set-aside program benefitting service-disabled veteran-owned small businesses. These procurements stipulate that Ontario Knife Co. be the supplier. The “prime contractor” is simply a middleman who profits from the transaction. To date, there have been three M10 contracts involving middlemen, for whom Ontario has been the supplier. |

Scabbard Body (front): "M10" and "ASSY 8448476" over "MFG 2V376" | ||||||

|

Ontario was awarded its first M10 Scabbard contract, DAAA-09-88-C-0129, in November 1987. The M10 Scabbard was a component packaged along with M7 Bayonets also made by Ontario. Cunningham reported a total of 58,100 in his 1996 book. This quantity is consistent with the total amount paid under the contract, so appears correct. | Label:

1005-00-017-9701 |

|||||||

|

Ontario was awarded contract W52H09-04-C-0222 on September 4, 2004. This contract was for M7 bayonets and M10 scabbards packaged separately. | Label:

1095-00-223-7164 |

|||||||

|

The example pictured at left is from contract W52H09-08-D-0004, a five-year contract awarded to Ontario in October 2007. Three delivery orders were placed for the M10 scabbard, totaling $42,469. The third delivery order was placed on May 25, 2010, for 3,000 scabbards in the amount $18,540. This suggests that the total quantity procured under this contract was approximately 6,900. The example pictured at left is one of 3,000 supplied under the third delivery order.

|

Label:

1095-00-223-7164 |

|||||||

|

This example is from the one of the Middleman contracts.

Contract SPE7L3-19-P-7158 was awarded to Harris Support Services LLC of Mosley, Virginia, in July 2019. This contract was for 9,960 M10 Scabbards. The packaging from these contracts have two labels, one bearing the middleman’s CAGE Code and the other Ontario’s. The bayonets and scabbards, themselves, are marked like all other Ontario examples. |

Label (front):

1095-00-223-7164 Label (reverse): 1095-22-223-7164 Scabbard Body (front): "M10" and "ASSY 8448476" over "MFG 2V376" |

|||||||

| Multi Purpose Bayonet System, M9 | Bayonet for use on the 5.56 mm. NATO caliber U.S. M16 assault rifle. Also used on U.S. Army combat shotguns, such as the Remington 870 and the Mossberg 500 and 590.

Adopted in 1986 as the Multi Purpose Bayonet System, M9, it remains the current-issue U.S. Army bayonet. Following extensive trials, the design submitted by a California engineering firm, Phrobis III, Ltd., outperformed more than 40 proposed designs, many submitted by well-known firms. The M9 is a much more sophisticated (and costly) bayonet than its predecessors. The M9's construction is heavier than the M4–M7 series bayonets; and, includes extra features like a wire-cutter and bottle opener. In addition, the M9 is a modular design, easily disassembled and repaired in the field. Procurement began in 1986. A total of 16 M9 bayonet contracts appear to have been let. U.S. government prime contractors and approximate years of production include: —Phrobis III, Ltd. (production by Buck Knives, Inc.): 1986–89, 1991 Approximately 321,127 Phrobis M9 bayonets have reportedly been produced for U.S. Government contracts (315,627 for the Army and approx. 5,500 for the Marine Corps). After Phrobis closed, Buck Knives produced 350 for Marine Corps trials. To date, Ontario appears to have produced over 215,000 under government contracts. Lan-Cay and Tri-Technologies are discussed below. All tolled, over 800,000 M9 bayonets appear to have been produced for U.S. Government contracts. Spare parts have also been procured (belt attachment, cutter, handle, latch plate, leg strap, scabbard, and sharpening stone). A feature of M9 production has been the introduction of design improvements on a flow basis, resulting in a bewildering number of variations. Collecting the M9 bayonet has become highly specialized, with many rare prototypes and variations to study. In addition to U.S. Government contracts, Buck, Lan-Cay, and Ontario all extensively produced the M9 and variants for commercial sale. Buck also produced approximately 33,500 for foreign military and security forces. Foreign producers have also made copies, some officially under license (e.g., Marto in Spain), but also many unauthorized knock-offs. A comprehensive history covering development of the M9 bayonet and production by Phrobis/Buck was published in 2018 by Richard Neyman in his book, M9 Bayonet: The Authorized History. Much additional history has been documented by Homer Brett, who was heavily involved with the M9 bayonet during its production. Many of these M9 resource documents are available on the MOCITYMAN web site. Additional information is available in the M9 Bayonet Contracts Summary. |

||||||||

| Pictures (click to enlarge) |

Type | Description | Blade Length |

Overall Length |

Muzzle |

Markings | |||

| in. | mm. | in. | mm. | in. | mm. | ||||

|

Lan-Cay Inc. | Lan‑Cay Inc. of Carrollton, Kentucky, was the successor to Phrobis III, Ltd., which closed after the government declined to exercise contract options for additional bayonets.

Lan‑Cay became M9 prime contractor in 1992, underbidding Buck who bid at cost in hopes of making their profit on commercial sales. Lan‑Cay appears to have been awarded eight M9 bayonet production contracts. Lan‑Cay was prime contractor from 1992–1998, after which they shared M9 production with Ontario Knife Co. Lan-Cay appears to have produced approximately 225,000 under government contracts. Lan‑Cay had no capacity to produce bayonet blades (they really just wanted to be the assembler). They initially subcontracted blade production to General Cutlery, Inc. of Fremont, OH. General Cutlery was a small firm that had previously manufactured M7 bayonets for the government. However, the complexity of the M9 blade and the M9s more exacting design standards were simply beyond their capacity to master. This forced Lan‑Cay to establish blade production capacity in-house (which they successfully did). Lan‑Cay founder and President, Barry Brown, passed away in 2011. The company subsequently closed and its machinery was auctioned off in 2013. This example was made in 1999, so is of the later or "product improved" M9 variant. The belt hanger was developed by Bianchi and is attached/detached via a Fastex connector. |

7.125 | 181 | 12.125 | 308 | .880 | 22.4 | Ricasso (left): "M9" over "Lan-Cay" over "USA"

Scabbard (body): "Lan-Cay"

|

|

This Lan‑Cay M9 bayonet was privately-commissioned in 2004 by the 98k Bayonet Collector’s Network (BCN) to commemorate the organization’s 10th Anniversary.

Dr. Jim Maddox approached Lan-Cay President, Barry Brown, who agreed to produce the bayonet with modifications designed by Maddox. The bayonet is the USGI Lan‑Cay Product-Improved M9 in production at that time, except for having the blade sandblasted (vs. black) and a black plastic (vs. green) ergonomic grip. The BCN S84/98 logo with a superimposed X is stamped on the ricasso opposite the Lan‑Cay maker mark. The scabbard is the Product-Improved Lan‑Cay variant in black, with black nylon suspension. A distinctive black nylon tool pouch with BCN embroidered in red is unique to this design. Only 76 of these bayonets were made, after which the special BCN striking die was retired so that no further examples could be produced. I unexpectedly found this example at a gun show and rescued it. Unfortunately, bubba had tried out the wire-cutter, marring the sandblasted blade finish. The BCN was hugely influential on the bayonet collecting community. Using a daily email digest, the BCN facilitated serious, scholarly discussion among collectors and researchers worldwide. The BCN’s example of sharing and collaboration for the benefit of the collecting community motivated creation of the worldbayonets.com site. |

Ricasso (left): "M9" over "Lan-Cay" over "USA"

Ricasso (right): BCN logo and "X" Pommel (latch plate): "Lan-Cay" Scabbard (body): "Lan-Cay" Scabbard (pouch): "BCN" Scabbard (belt hanger Fastex connector): "ITW Nexus" and mfr date of March 2002 |

|||||||

|

Tri-Technologies, Inc. | Tri-Technologies, Inc. of Mt. Vernon, New York was awarded contract W56HZV-12-C-0327 in September 2012 for 40,000 M9 bayonets with scabbards. The contract included an option for an additional 40,000 bayonets, however, this was never exercised.

The company was founded in 1996 and manufactures small parts and components for military and commercial equipment. 06MA8 is Tri-Technologies' Commercial and Government Entity Code (CAGE Code). The original delivery schedule anticipated provision of 40,000 bayonets by December 2014. In October 2013, the delivery schedule was extended to May 2015. The government terminated the contract for convenience in September 2016, At one time, I thought that the contract was terminated before all 40,000 were delivered. However, further analysis suggests that all 40,000 were likely delivered. At present, these are the last M9 bayonets produced for a U.S. Government contract. |

Ricasso (left): "M9" over "06MA8" over "USA"

Scabbard (belt hanger Fastex connector): "ITW Nexus" and mfr date of 2–14 |

||||||

| OKC3S Multi Purpose Bayonet | Bayonet-Knife for use on the 5.56 mm. NATO caliber U.S. M16 assault rifle. Also used on combat shotguns, such as the Remington 870 and the Mossberg 500 and 590.

During the 1990s, the U.S. Marine Corps conducted extensive trials of the M9 bayonet, twice declining to adopt it. In 2001, they sought an off-the-shelf product from existing bayonet makers, eventually selecting a made-in-USA version of the AES Bayonet 2000. However, resulting political upheaval over selecting a European design killed the deal. A proposed design by Ontario Knife Co. of Franklinville, New York, was adopted by the U.S. Marine Corps in December 2002 as the Bayonet, Multi-Purpose. Because it was procured as an off-the-shelf item, it was not given a "M" designation. The Ontario Knife Co. designation for the version adopted was OKC3S, which represents Ontario Knife Co. design no. 3 with Serrations. It remains the current-issue U.S. Marine Corps bayonet. The OKC3S bayonet and scabbard was assigned National Stock Number (NSN) 1095-01-506-3424 on March 27, 2003. NSN 1095-01-506-3424 was discontinued and replaced by NSN 1095-01-521-6087 on June 25, 2004. Deliveries began in 2003 and last occurred ca. 2011. Ontario Knife Co. has been the sole supplier. A total of 12 OKC3S bayonet contracts appear to have been let. Spare parts have also been procured (carriers, leg straps, scabbards, and a few replacement bayonets without scabbards). Approximately 150,000 OKC3S bayonets appear to have been produced under U.S. Government contracts. In addition to government contracts, Ontario has also produced the OKC3S and variants for commercial sale. Some OKC3S bayonet history has been documented by Homer Brett, who was heavily involved with the OKC3S bayonet during its adoption. Some OKC3S resource documentss are available on the MOCITYMAN web site. Additional information is available in the OKC3S Bayonet Contracts Summary. |

||||||||

| Pictures (click to enlarge) |

Type | Description | Blade Length |

Overall Length |

Muzzle |

Markings | |||

| in. | mm. | in. | mm. | in. | mm. | ||||

|

OKC3S Bayonet & Scabbard with Carrier | The OKC3S is of full-tang, peened construction, eliminating the inherent weakness (as the Marines saw it) of the M9s modular design.

The OKC3S blade is longer, thicker, and more pointed than the M9 bayonet. The blade was designed to penetrate the body armor that Marines were increasingly encountering in Afghanistan. The blade profile is also reminiscent of the USMC's beloved KA–BAR knife. Both the true edge and long false edge are very sharp. The true edge has deep serrations near the ricasso, for cutting rope and heavy materials. The scabbard has a ceramic honing rod on the reverse. The integral web frog measures 14.00 in. (356 mm.) long by 1.375 in. (35 mm.) wide. It is designed for use with the MOLLE/PALS load-bearing systems used by the USA and many NATO countries. MOLLE = Modular Lightweight Load-carrying Equipment. PALS = Pouch Attachment Ladder System.

|

8.00 | 203 | 13.125 | 333 | .880 | 22.4 | Ricasso (left): "Combat" over "U.S.M.C."

Ricasso (right): "OKC 3S" over "Ontario" over "Knife Co." Grip (left): Eagle, Globe, & Anchor logo Grip (right): "USMC" |

|

OKC3S Nylon Leg Strap | Nylon leg strap used with the OKC3S Scabbard.

This strap performs the function of the Restraining Lace included with the M8A1 and M10 scabbards. It is made of 1.0 in. (25 mm.) wide nylon strap, adjustable in length up to 34 in. (86 cm.). The color is Coyote Brown. Ontario Knife Co. is the exclusive prime contractor for this item, which is included in the indefinite-delivery contracts awarded for the OKC3S bayonet, scabbard, and components. The example pictured at left was packaged in July 2007. |

n/a | n/a | n/a | Label:

NSN 8465-01-507-5635 |

|||

|

OKC3T Training Bayonet | Developed by Ontario as a follow-on to the OKC3S, the OKC3T was designated Trainer, Bayonet and assigned NSN 8465-01-539-3492 on April 19, 2006. The OKC3T is classified as an item of Individual Equipment, not a Weapon.

The OKC3T Training Bayonet can be used mounted to the M16 for fencing and dismounted for training in hand-to-hand combat. The OKC3T is of similar construction as the OKC3S bayonet above, save for the blue plastic sheathing that encases the steel blade stub. Consequently, it is the same size and weight as the real thing and will stand up to considerable abuse. Only a few U.S. Government prime contracts are recorded for this item, suggesting that they may also have been purchased using less formal means, such as requisitions and credit card payments.

|

8.00 | 203 | 13.25 | 336 | .880 | 22.4 | Blade: "OKC3T Training Bayonet" over "Ontario Knife Company" over "Made in U.S.A." |

|

Cobray M11/Nine | Folding socket bayonet made for the 9 mm. Cobray M11/Nine pistol.

The blade is from a folding throwing knife patented in 1977 by the famous firearms designer, Maxwell G. Atchisson. Atchisson was an engineer at Military Armament Corporation (MAC), working with MAC 10/11 machine pistol designer, Gordon Ingram, and Sionics silencer designer, Mitch WerBell. S.W.D Inc. operated from 1982–94. Atchisson joined S.W.D Inc., where they produced his folding throwing knife. S.W.D. had rights to the MAC 10 design and Cobray trademark, under which they sold an immensely popular semi-automatic version, the M11/Nine. Aggressively marketed as "the gun that made the 1980s roar," the M11/Nine became notorious in the hands of criminal gangs, leading to enactment of the 1994 Federal Assault Weapons Ban. When S.W.D. stopped selling the Atchisson knife, they made a bayonet socket for the M11/Nine barrel in order to utilize the leftover blades. The socket fits over the threaded barrel and a hex nut secures it. Although still in the original box, the hex nut is missing from this example. The original blade stamp included the throwing knife patent number, so they milled that off blades used for the bayonet. |

5.375 | 137 | 6.625 | 168 | .735 | 18.7 | Blade: "S.W.D. INCORPORATED" over "ATLANTA, GEORGIA" and Cobray trademark |

|

|

Ruger 10/22 | Commercial knife bayonet for display use with the .22 LR caliber Ruger 10/22 rifle.

The bayonet is part of the Archangel Manufacturing LLC, 5.56 mm. Advanced Rimfire System kit that alters the rifle into a tactical configuration. The bayonet is intended for display only, however is made of high-strength polymer and has a surprisingly sharp edge and point. Definitely not a child's toy. Two bayonet variations exist, one patterned after the U.S. M7 and another with a prow or "tanto" point. The bayonet mount fits over the Ruger 10/22 factory barrel and front sight. Archangel Manufacturing LLC began in 2008 as a subsidiary of Brookshire Tool and Mfg. Company, Inc. of South Gate, CA. In 2013, the owner of Brookshire Tool & Mfg. formed Pro-Mag Inc. in Phoenix, AZ, then merged Brookshire into Pro-Mag in 2014. Pro-Mag continues to offer the Archangel product line today. |

6.25 | 159 | 11.00 | 279 | .945 | 24.0 | Ricasso; "Archangel" |

| Back | Next | ||||||||

| Return to Bayonet Identification Guide Index | |||||||||

| © Ralph E. Cobb 2009 All Rights Reserved | Top | ||||||||